Understanding the 5 Key Components of a Resilient Supply Chain

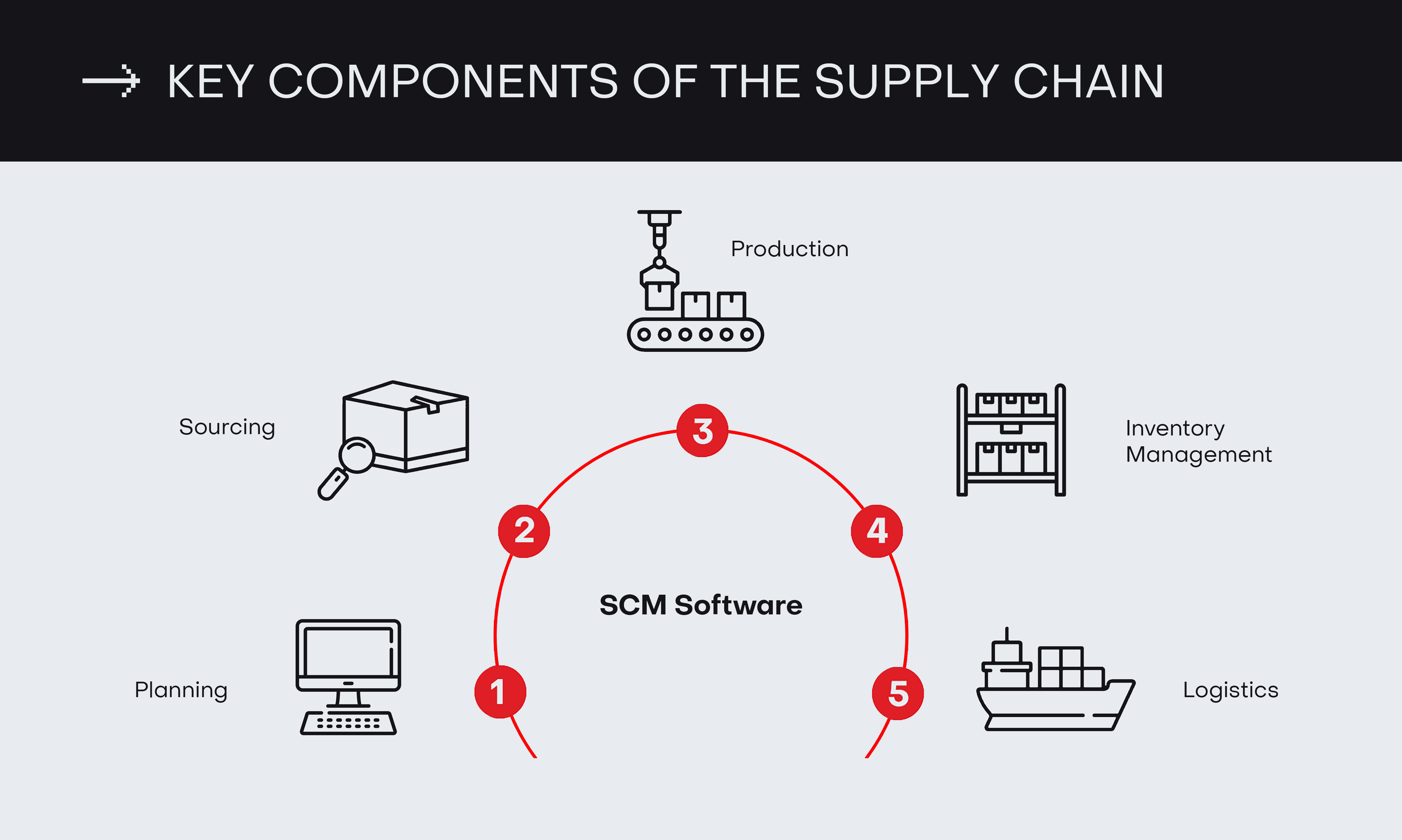

Supply chain management (SCM) encompasses a broad spectrum of processes essential for efficiently orchestrating the entire journey of a product, from sourcing raw materials to crafting the final masterpiece and distributing it economically.

By integrating a series of strategic actions, SCM optimizes the seamless flow of goods, services, information, and costs across crucial stages: planning, sourcing, production, inventory management, and logistics. To gain a competitive edge, companies employ a combination of well-defined supply chain strategies and advanced management software.

The success of supply chain management relies on the collective efforts of all participants involved—ranging from suppliers and manufacturers to every link in the chain—to ensure its seamless operation. Achieving this level of efficiency demands strong change management, cooperation, and risk management, fostering alignment and collaboration among all partners.

Supply Chain Hurdles: Tackling Obstacles Head-On

Disruption and uncertainty have become the norm for the global supply chain, with 82% of supply chain leaders anticipating challenges to worsen or remain the same in the next 6 to 12 months. In 2022, over 80% of organizations experienced significant disruptions, and supply chain leaders predict that food, gas, and computer chips are most at risk of impact in 2023.

The biggest challenges for supply chain leaders include:

- increased costs,

- geopolitical uncertainties,

- transportation capacity shortages,

- critical parts shortages, and

- uncertainty in customer demand.

To address these issues, building healthy supplier relationships has become a top priority, and many companies are implementing strategies like reducing supplier dependency on a single region, relying on geographically closer suppliers, and strengthening relationships with current suppliers and buyers.

Investing in digital supply chain solutions is crucial for enhancing agility and resiliency. While 79% of leaders plan to invest in such solutions in 2023, there is still progress to be made, as many functions remain undigitized. Digitization is seen as a key factor in ensuring product availability, improving customer experience, and reducing overall risk in the supply chain.

Now might be a good time for businesses to start rolling out data-driven processes to improve their overall supply chain.

Key Supply Chain Steps for Smooth Operations

An efficient and well-optimized supply chain is crucial for companies to stay competitive and deliver value to their customers. The supply chain encompasses a complex network of processes, people, and resources involved in the flow of goods and services from raw material sourcing to the final product delivery.

To ensure smooth operations and minimize disruptions, organizations must pay close attention to several key supply chain steps.

Let’s explore these essential stages and how they contribute to a successful supply chain:

1. Planning

To kickstart the supply chain process, thorough strategy development and planning are essential. This involves investigating product demand, viability, expenses, profits, and human resources.

Supply chain management begins with figuring out what products customers crave, or demand planning, where historical data and analytics are used to forecast product demand. This plan is then agreed upon by sales, manufacturing, and marketing departments to determine the types and quantities of products to be produced.

Some companies formalize demand planning as part of a process known as sales and operations planning (S&OP), involving data gathering, discussion, alignment of demand and production plans, and management approval. Others consider it a facet of integrated business planning (IBP), incorporating various departments’ programs into a cohesive, company-wide plan.

The subsequent critical stage, production planning, focuses on determining the specific details of product manufacturing as outlined in the demand plan. Advanced planning and scheduling, typically automated through specialized software, refine and adapt production resources to fluctuations in demand.

Material requirements planning (MRP) plays a key role in ensuring the availability of necessary materials and components for the manufacturing process. Responsible managers conduct inventory assessments, identify gaps, and procure or produce the required items. The bill of materials (BOM), a comprehensive list of elements needed for product creation, serves as a pivotal document in both MRP and production planning.

MRP can be incorporated into manufacturing resource planning (MRP II), extending its scope to encompass other departments, such as Human Resources and Finance. These concepts serve as the precursors to enterprise resource planning (ERP), software designed to integrate vital business processes across the entire company.

The importance of formulating a well-thought-out plan and strategy cannot be understated. It lays the groundwork for reaping the benefits and success in the complex world of supply chain management. Devoting sufficient time and attention to this aspect is imperative for businesses aiming to thrive in their supply chain endeavors.

2. Sourcing

Sourcing, or procurement, is a vital stage in the supply chain management process. The goods and services offered to customers are created using various raw materials, making it crucial to find dependable suppliers who provide high-quality materials at reasonable costs. Effective communication, such as sending out bid requests and handling documentation like purchase orders and invoices, is also essential.

Ideally, all supply chain players—suppliers, manufacturers, distributors, and retailers—should have dedicated procurement staff. Timely delivery of products within the budget is crucial for avoiding losses and maintaining a positive reputation for the business.

Strategic Sourcing

Strategic sourcing is an elevated and advanced approach to supply management, seeking to enhance a company’s sourcing process by leveraging consolidated purchasing power to align with overall business goals.

While the most evident advantage of strategic sourcing is a decrease in total costs, its impact extends far beyond that. As companies tap into vast pools of available data and embrace digitalization in business processes, procurement becomes an area ripe for transformation.

Benefits of strategic sourcing:

- Transformation of supply within the company: 74%

- Elevated productivity through automation: 65%

- Increased savings: 61%

As Gartner’s Magic Quadrant for Strategic Sourcing Application Suites states, implementing strategic sourcing brings significant benefits. The primary reason, identified by 74% of organizations, is the transformation of the supply chain within the company. Additionally, elevated productivity through automation (65%) and increased savings (61%) are key drivers for adopting strategic sourcing practices.

In the quest for high-quality raw materials to create top-notch products and maintain a stellar market reputation, dedicated suppliers become the most sought-after participants in the supply chain management system.

Applications of strategic sourcing

A strategic sourcing plan can help businesses achieve various goals that lead to success, including:

- Managing environmental conditions and logistics by sourcing goods in locations where they are readily available or easily transported.

- Achieving competitive differentiation by partnering with suppliers with desired brand images and emphasizing them through marketing (e.g., The Intel Inside logo).

- Ensuring compliance with regulatory guidelines by selecting certified components.

- Supporting business sustainability by choosing sustainably grown or sourced products.

- Mitigating geopolitical instability by diversifying supplier locations and creating contingency plans for those in volatile areas.

- Minimizing risk by collaborating with alternative suppliers and monitoring changes such as product availability, quality, shipping, taxes, exchange rates, and regulations.

3. Production

For the production process to begin, proper planning, the supply of goods, and inventory management are essential. In production planning, the first decision is to determine which type of production process best aligns with business goals and customer demand.

There are three prevalent types of production: mass production, mass customization, and customization. Additionally, operations managers also categorize production processes into two stages: converting inputs into outputs and determining the timing of the process.

- Mass Production: Highly identical products or services; examples include breakfast cereals, computer keyboards, and soft drinks.

- Mass Customization: Uniform standardized manufacturing to a point, with unique features added to each product; examples include Nike By You footwear, sporting goods by Atomic Skis, and eyewear by Warby Parker.

- Customization: Each product or service is tailored to individual customer demand; examples include custom homes, legal services, and haircuts.”

As mentioned above, production involves converting inputs (natural resources, raw materials, human resources, budget) into outputs (goods or services). In a manufacturing company, the inputs, production, and outputs are usually obvious.

Nike, for instance, converts plastic, rubber, paint, and other inputs into footwear. But the production process in a service company incorporates a less obvious conversion. For instance, a law school converts the knowledge and skills of its staff, along with equipment and supplies, into legal services for people.

Production Timing:

- A continuous process uses long production runs and lasts for days, weeks, or months without turning off the machines. It best fits high-volume, low-variety products with standardized parts, such as tires, glass, or paper. Per unit expenses are low, and production is easy to schedule.

- An intermittent process uses short production runs for manufacturing batches of different products. Instruments are shut down to change them to make various products at different times. It best fits low-volume, high-variety products made by mass customization or customization.

The production is followed by testing, packaging, and the last preparation for shipment. When this part of the supply chain is done, it’s time for inventory management to begin.

4. Inventory Management

Inventory management is a sophisticated process, especially for giant corporations, but the basics are often the same regardless of the company’s size or type. In inventory management, products are transported into the receiving area of a warehouse and are forwarded into stock areas or shelves.

As a component of the supply chain, inventory management involves the flow of products from manufacturers to warehouses and from these facilities to retailers.

Inventory Management Software System

To ease the work inside a warehouse and to automate the entire process of inventory management, companies started using software systems. Initially, inventory management (IM) software was simple spreadsheets that traced the quantities of goods in a warehouse.

Nowadays, IM software can go more in-depth and integrate with accounting and ERP systems. These systems keep track of goods in inventory, sometimes across several warehouse locations. The software also estimates the costs—often in multiple currencies—so that accounting systems always have an accurate estimation of the value of the goods.

As studies show, companies can gain a 25% increase in productivity, 20% better space usage, and a 30% improvement in stock use efficiency if they opt for an integrated order processing for their inventory system.

Inventory management software for large companies can also be greatly customized for the particular needs of those enterprises. Massive systems that were previously run on-premises are now also located in public, private, or hybrid cloud environments. Small and midsize organizations typically don’t need elaborate and expensive systems, and they often rely on standalone inventory management products, generally through SaaS applications.

Benefits of using IM software:

- Easier stock level tracking and taking inventory through scanning and saving data

- Real-time access to inventory data and stock levels

- Fewer human errors through digitization of paperwork

- More control over data, such as invoices, sales, profit margins, etc.

- Minimized loss of sales and keeping up with demand

- A practical and time-saving flow of the goods

- A steadier inflow of products in line with product outflow

- Real-time access to product demand

Inventory Management Techniques

IM has several ways to keep the right amount of products on hand to satisfy customer interest and operate effectively. This task is particularly complicated when companies need to deal with thousands of stock-keeping units (SKUs) across multiple warehouses. The techniques include:

- The Stock review methodology is generally more suitable for small businesses. The stock review involves regular analysis of stock available versus predicted future needs. It mainly uses manual effort, and while it can provide a measure of control over the inventory management process, it can be labor-consuming and prone to mistakes.

- The Just-in-time (JIT) strategy attempts to increase efficiency and decrease sales loss by receiving goods only as they are required in the production process, thereby reducing inventory costs. This method expects producers to predict demand accurately. The advantage of JIT is that there is no need to keep tons of products on hand to meet customer demand. However, risks may arise. Misreading market demand or having distribution issues with suppliers can lead to out-of-stock problems.

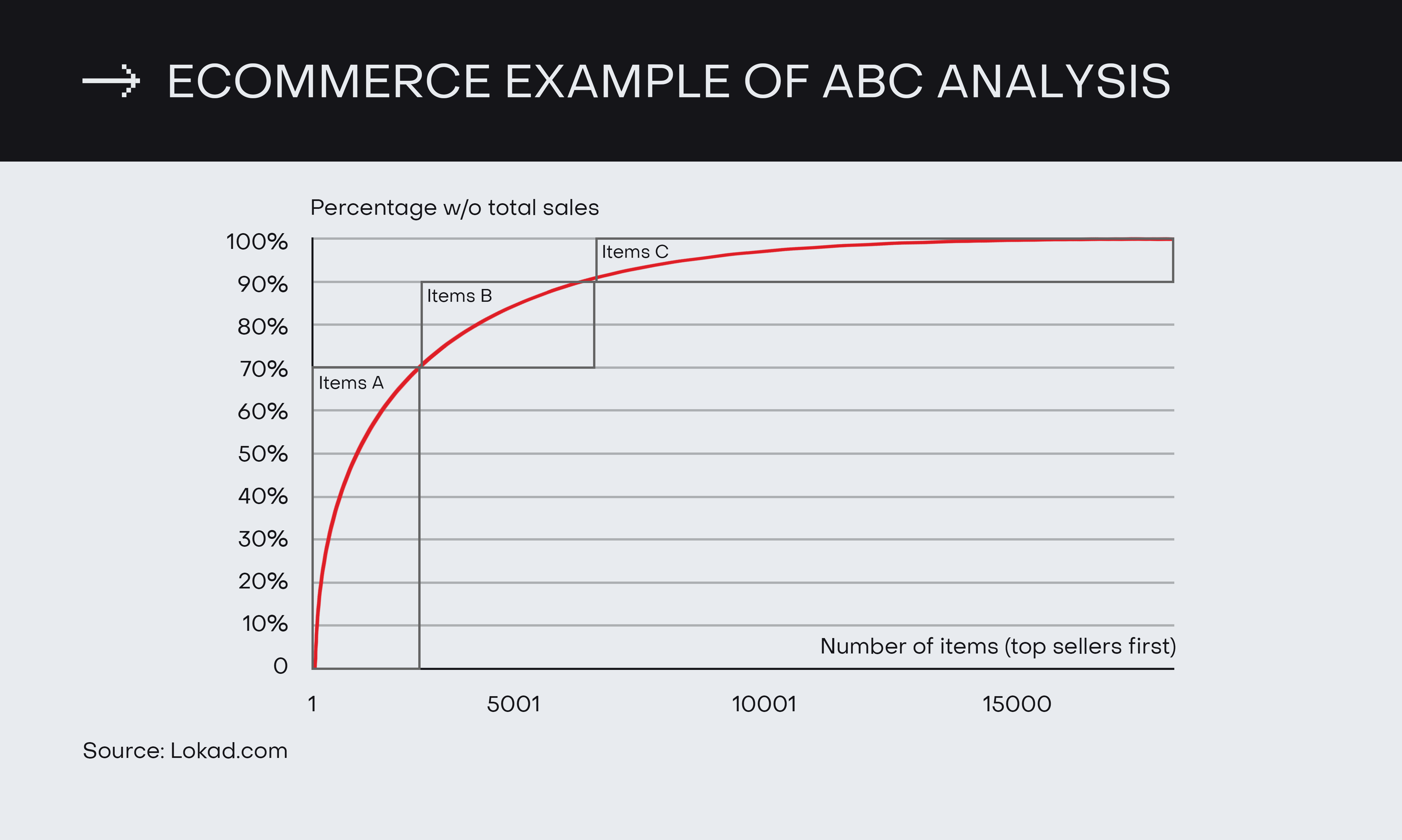

- ABC analysis is a method of IM that divides sales items into three categories: A, B, and C, according to their cost and value. A-category represents the top sellers and C corresponds with the slow movers. This method aims to draw executives’ attention to the critical few (A-items) and not on the trivial many (C-items). This analysis allows companies to keep costs under control within the supply chain. Plus, to get the most from management efforts, it is efficient to focus on products that cost most.

The purpose of inventory management is to minimize the total cost of inventory and to maximize the capability of providing customers with the ordered products on time. In accomplishing this goal, efficient logistics management has to take place.

5. Logistics

The two primary tasks of logistics are transportation and warehousing. Transportation management tasks involve planning, optimizing, and executing the use of transports to move goods between warehouses, retailers, and points of consumption. There is a wide range of vehicles involved in the delivery process: ocean, air, rail, and road transport.

A sophisticated delivery process comprises planning and optimizing routes, shipping loads, order management, freight audit, and payment. It can also involve yard management, a process that supervises the movement of transport through the yards outside plants, warehouses, and distribution facilities. Carrier management is also a vital aspect since the cost, availability, and capacity of transportation carriers can fluctuate greatly.

To fulfill the transportation tasks, companies typically address logistics software development. Businesses may use more specific solutions like transportation management system (TMS) software or yard management systems.

Warehousing, or warehouse management, has to deal with inventory management and order fulfillment. It also involves handling warehouse infrastructure and processes. For example, in the fulfillment center, orders for goods are received, processed, and shipped to the customer.

Most companies use a warehouse management system (WMS) to manage the flow and storage of goods and track inventory. Innovecs, in turn, can offer TMS and WMS modules, as well as more specialized components for logistics and supply chain management. Consult Chapter 6 of the article to learn more about Innovecs expertise.

Customs management, or global trade management, is also considered to be part of logistics since the documentation to show compliance with government regulations must be processed where products cross national borders or enter shipping ports.

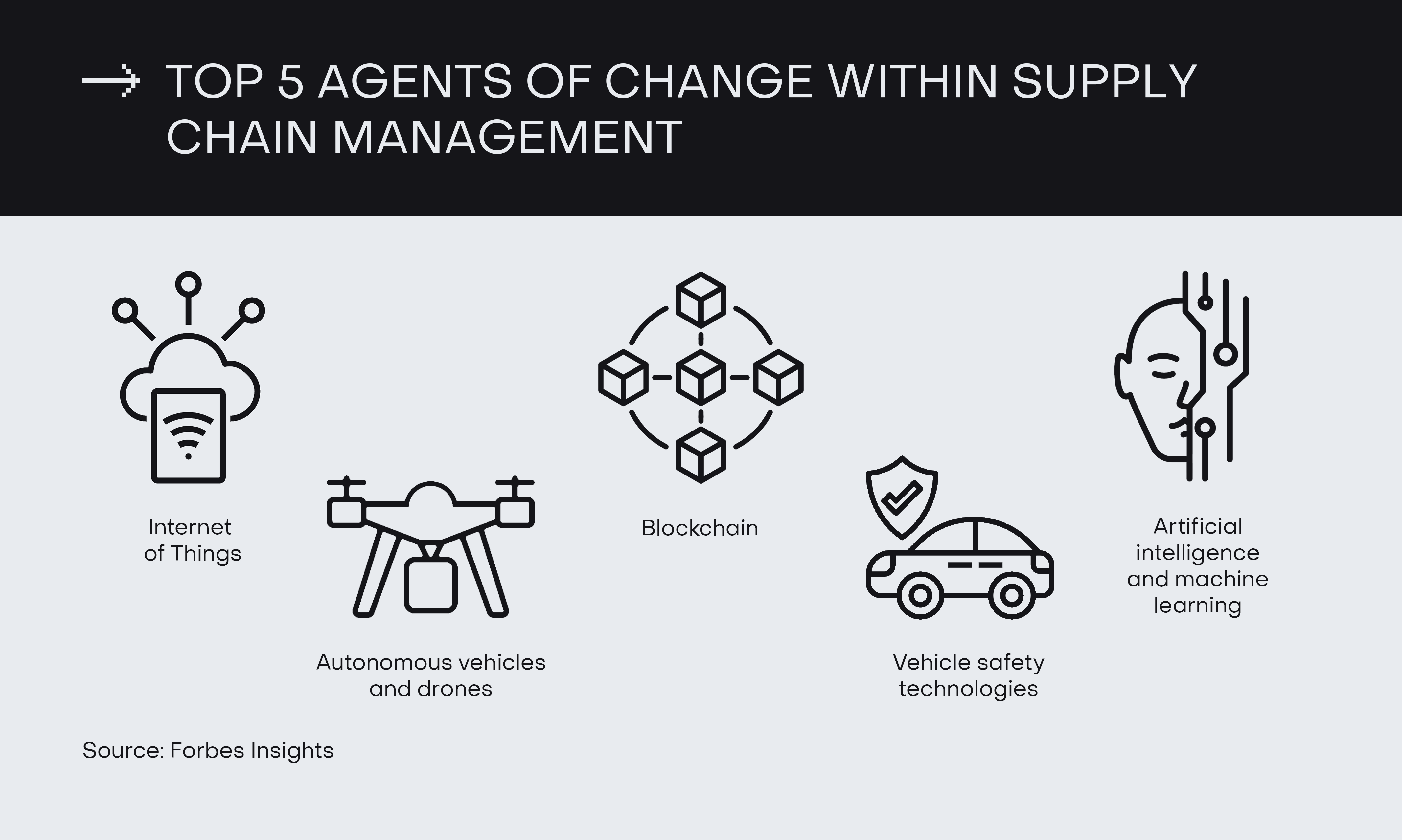

Artificial intelligence (AI) and driverless vehicle technology are going to change the way logistics operates in the near future. Some providers already use AI to better track orders and forecast transport-related issues in the supply chain.

Meantime, autonomous vehicles, such as driverless forklifts, delivery trucks, and drones, are gaining popularity in warehouses, warehouse yards, and on highways.

Suppliers, manufacturers, distributors, and retailers must upgrade their logistics processes to keep up with innovations and meet the demand for quicker, more timely delivery of a wider assortment of goods. They must also better integrate their processes and systems to increase supply chain visibility.

Return of goods

Among the various elements that create a reliable supply chain is an ability to return damaged or malfunctioning products, in conjunction with a highly responsive customer support service.

No one is perfect. Even a machine may fail once in a million times, if not more. As a part of a robust business process, expect the return of goods due to specific conditions. Even high-quality quality control processes may have inevitable slips. In the case of such lapses, undoubtedly followed by customer complaints, a company must recall the product(s) and issue an apology. This not only builds a good relationship with customers but also maintains goodwill in the long run.

6. Build a reliable supply chain with robust SCM software

Technology is crucial in managing today’s supply chains, and every significant supply chain management component has a software category dedicated to it.

Besides managing specific processes, supply chain management software plays a vital role in tying together the people, operations, and systems included in the supply chain.

The commonly used SCM modules include the following:

- Transportation management system (TMS) for organizing the transport and storage of goods, particularly across worldwide supply chains

- Warehouse management system (WMS) for all of the operations inside warehouses and distribution centers

- Order management system to handle the processing of the orders through WMS, ERP, and TMS systems at all stages of the supply chain

Driving Business Using Automated WMS

Innovecs’ expertise offers a broad spectrum of software solutions to streamline the processes inside your supply chain, taking it to the next level. In particular, our engineers have mastered the development of a robust WMS from scratch. By collaborating with the Innovecs team, you’ll get feature-rich WMS system with the following functions:

- Warehouse design that allows organizations to customize workflow and pick logic to ensure that the warehouse is designed for optimized inventory allocation. The WMS establishes bin slotting, which maximizes storage space and accounts for variances in seasonal inventory.

- Inventory tracking that allows the use of advanced tracking systems, such as radio-frequency identification (RFID), automatic identification, data capture (AIDC), and barcode scanners to ensure that goods can be easily accessible if they need to be moved.

- Receiving and putaway performed using pick-to-light or pick-to-voice technologies, which helps warehouse employees to better and quicker locate goods in storage.

- Pick and pack fulfillment, including batch picking, wave picking, and zone picking. WMS can help to detail which box will be the most suitable option for the order at hand. Operators can also use lot zoning and task interleaving functions to do the pick-and-pack tasks most efficiently.

- Shipping fulfillment that enables the WMS to send bills-of-lading (B/L) as soon as the shipment is sent, generate packing lists and invoices for the delivery, and send advance shipment notifications to consumers.

- Labor management that helps warehouse supervisors regulate workers’ performance by using key performance indicators (KPIs) that show which workers overwork or underwork.

- Task management that aids in managing employees’ daily workflow by setting daily duties, tracking working time, and streamlining the overall processes inside the warehouse.

- Yard and dock management allows truck drivers to come into a warehouse and quickly find the right loading docks. More sophisticated use of yard and dock management enables cross-docking.

- Reporting that helps executives analyze the performance of warehouse operations and find gaps to improve.

The Advantages of Using WMS

Reduced operating costs

A well-designed WMS reduces operating costs in many ways. For example, some advanced systems simulate the warehouse floor and create digital floor plans within the system. These digital simulations let operators place pallets, shelves, and other equipment they need to accommodate in a warehouse.

Better inventory visibility

Better inventory transparency is one of the most critical tasks for warehousing. With WMS software, you can get real-time access to inventory data through barcoding, serial numbers, and RFID tagging. Plus, WMS solutions enable inventory tracking within a single warehouse or multiple locations.

If you want to be sure that you always have an eye on all operations, you might want to consider implementing solutions and SCM systems on the market to gain more transparency in your supply chain. The statistics below reveal how weak the attitude of companies regarding the visibility in their SCM is.

Enhanced security

Most warehouse management applications require workers to use individual user accounts for their activities. This creates an audit log report that connects specific workers to specific operations, which improves accountability and reduces the risk of theft, unauthorized access to confidential data, and other issues.

Inbound and outbound optimization

A warehouse management system provides inbound planning tools for scheduling and putaway fulfillment. With these tools, you and your supplier can decide what date and time are best to receive a shipment based on the resources and equipment available.

Increased labor efficacy

In addition to improved inventory placement and route management, WMS can determine the best team member for a particular task. WMS can analyze factors such as skill level or proximity to help users assign tasks to each employee.

Improved team spirit

A robust WMS platform isn’t a cure-all for every issue within your workforce, but it can do a lot to alleviate the difficulties both leadership and manual workers face in everyday jobs. A well-organized work environment can give your employees that extra time to think twice before attempting an inaccurate lift or using defective equipment. This all adds up to a healthier workplace, more enthusiastic and satisfied workers, and further growth of your business.

Improved relations with customers and suppliers

The advantages of using a warehouse management system go far beyond the company itself. With high inventory traceability and the ability to schedule the receipt of packages, both supply and demand chains are improved with the use of a WMS.

Suppliers see a reduced wait at docks and loading bays, while customers enjoy overall improved order fulfillment, reduced delivery times, and fewer order inaccuracies. The image of your business among consumers and suppliers will improve under such a system.

The benefits mentioned above are only a part of full WMS capability. A well-designed warehouse management software is the best way to quickly improve the success and profitability of your business.

Managing Warehouse Documents Electronically

Another solution provided by Innovecs is digital document storage, along with e-signing of all the papers processed within your supply chain. Electronically manage forms, certificates, and other valuable warehouse documents.

Warehouse data management—everything from logistics and freight forwarding to inventory management, to wholesale distribution—all benefit from digital document management. Most processes involve paperwork, and universal document storage can transform the paper trail into an integrated system that electronically manages entire warehouse documentation.

What you get with digital document storage:

A faster warehouse — warehouse document management accelerates the retrieval and access to paper documents so that team members can answer questions faster and warehouse inventory can move more quickly. In accounting, instant access to files supports faster billing.

Import-export compliance — maintaining valid certificates, and complying with regulatory restrictions, requires detailed monitoring of deadlines, expiration dates, and other warehouse document milestones. Records management tools and reminders aid in automating the process for renewals and re-certifications, so people stay informed before it is too late.

Invoice automation speed accounts payable — go paperless with electronic invoice processing. Invoices can be quickly converted into the digital system, routed for approval, and prepared for processing. Fast turn around improves cash flow.

The advantages of digital document management:

- Turn and handle all warehouse documents to a full-text and searchable digital format.

- Manage documents according to any number and combination of metadata, from SKU, to certificate, to customer ID.

- Dramatically increase the retrieval efficiency of paper warehouse records to speed up warehouse operations and back-office efficiency.

Revolutionizing Your SCM: A Comprehensive Guide to Enhancing Supply Chain Management

In this comprehensive guide, we’ve dissected the fundamental components of supply chain management, emphasizing the crucial importance of their seamless integration to ensure success while minimizing bottlenecks.

To expedite your processes and mitigate the risk of human error, it’s imperative to fortify your entire supply chain. Exploring a range of SaaS solutions, such as inventory management platforms, warehouse management systems, SCM tools, and BPM solutions, can be a game-changer.

The decision of whether your business should adopt these tools ultimately rests with leadership. Our aim has been to provide you with valuable insights into the evolving landscape of the industry, shedding light on the transformations in supply chain processes, challenges, and best practices.

Before you embark on these product investments, we encourage you to explore Innovecs’ expertise. This will not only enhance your comprehension of the multifaceted role of SaaS across various industries but also help you harness its potential for the benefit of your company.