Real-Time Supply Chain Visibility: Best Solutions To Keep Shipping Operations Transparent

Article updated on June 24, 2022

Lack of B2B interaction and inventory visibility can become a real challenge, especially under the tight competition between companies striving to achieve “one-day delivery” for more customers’ satisfaction.

Custom or ready-made software solutions can boost the ability of the stakeholders to access real-time data relevant to the order process, inventory, delivery, and potential supply chain disruptions.

Coca-cola, Best Buy, Walmart, Kraft Heinz, and many more industry giants are using visibility tools.

In today’s competitive markets, companies are tasked with being notified of every product movement in their supply chain operations. Whether it’s an ocean container, pallet/skid, truck in transit, or drone delivery there is a growing need to keep track of every shipment in real-time. The end-game is to offer the best service and make sure customers are extremely satisfied with 5-star recommendations.

At Innovecs, we have been part of the supply chain and logistics world since 2012. We have helped companies automate their warehouses, integrate with ports and carriers, create online freight marketplaces, and manage their transportation systems. In this article we are going to break down the nuances of real-time visibility to uncover the following:

- Why achieving visibility in your supply chain is a challenging task

- The importance of real-time visibility for your business

- The benefits of having a strategy in place

- Technologies that can drive visibility across all supply chain stages

The Challenging Nature Of Supply Chain Visibility

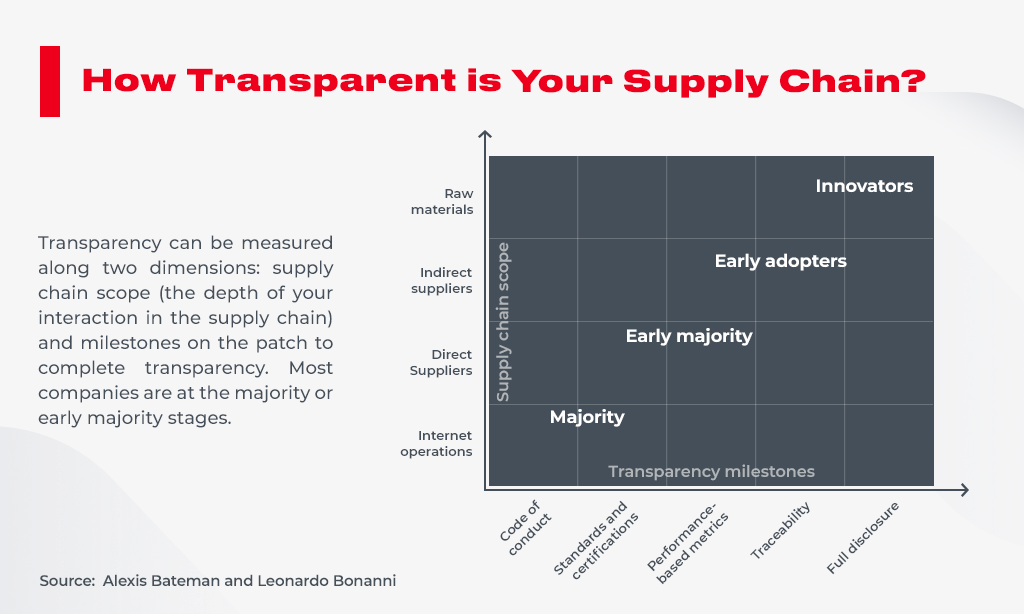

While companies are now transforming their linear supply chains into complex multilayer digital networks, tracking operations and keeping them transparent to all stakeholders has become more difficult. For example, a single product can interact with hundreds of people on its journey from manufacturing to delivery. And as the amount of data for analysis and monitoring grows, so does the need for increased security.

Achieving real-time supply chain visibility can come with unforeseen difficulties:

- Lack of high-quality, reliable, and well-structured data for tracking operations

- Process inefficiencies and a lack of understanding of the benefits of better visibility

- Poor risk management within your supply network

- Inability to effectively handle supply planning and demand forecasting

- Educating your personnel on how to use the insights from real-time visibility (even if it’s already integrated into your supply chain)

ASOS Fashion, an online clothing brand, faced difficulties in 2019 with synchronizing their available stock of merchandise and their website. At first glance, this type of inventory visibility should not be a problem. ASOS was using an automated system for monitoring their products departing the warehouse to fulfill orders. Still, the system was not tracking incoming products to the warehouse or any returns from their customers. This lasted for weeks and cost ASOS and their investors about $30 Million.

This is a prime example of the complex nature of supply chain visibility and how much preparation has to be made to achieve full transparency. Even the most basic fulfillment systems have bottlenecks; imagine how complex supply networks covering many stages can be!

What is Supply Chain Visibility and How Important is it for Businesses?

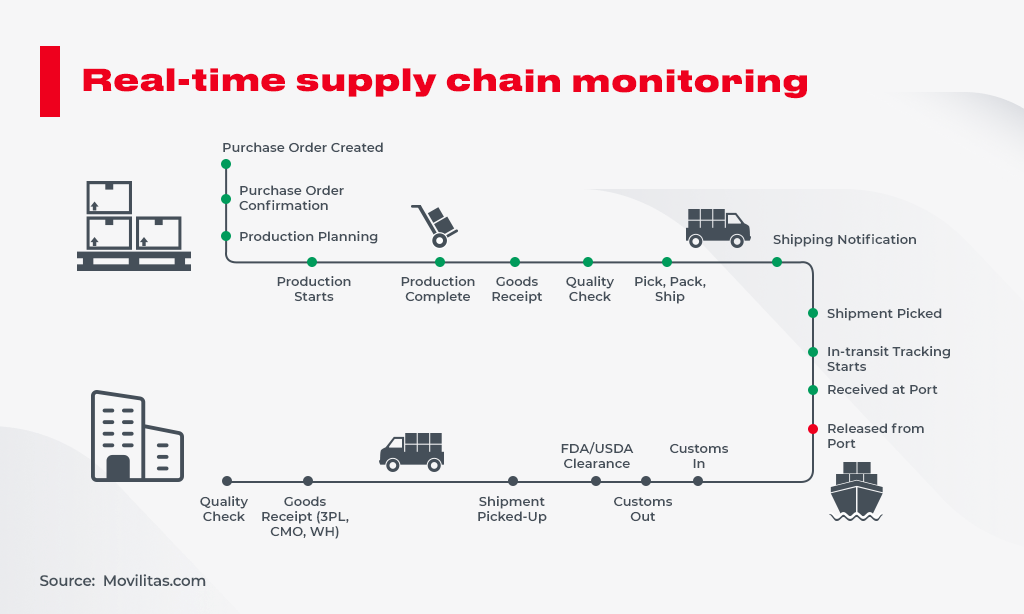

Supply Chain Visibility (SCV) technologies provide a major benefit by allowing companies to trace their products through the entire transport journey; from the point-of-sale (POS) to a customer’s doorstep. The goal is to enhance and fortify the entire supply chain by granting access to data to all process participants 24/7.

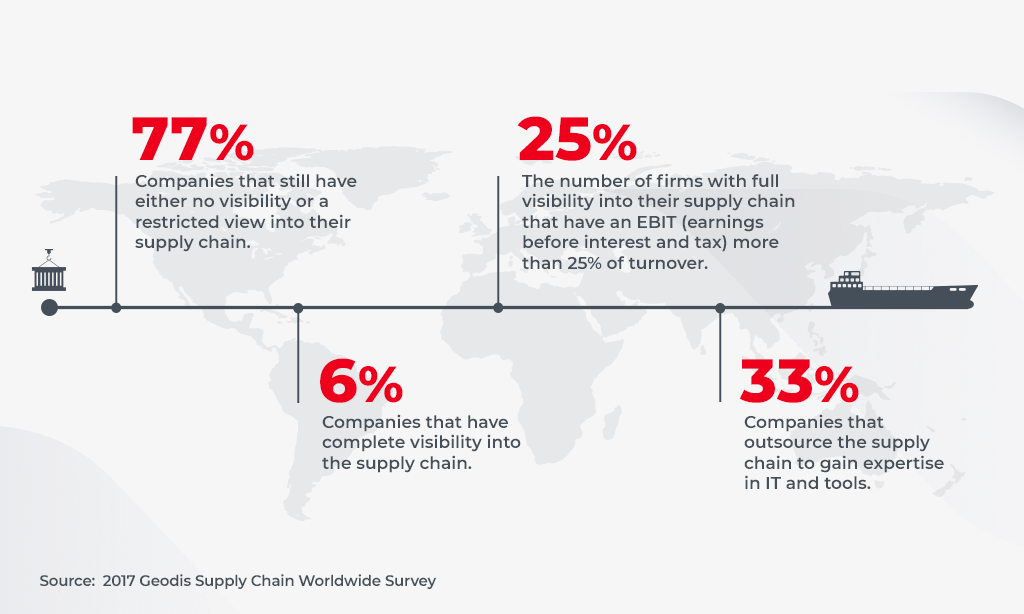

Online supply chain visibility solutions are responsive and stable at the same time. When facing severe disruptions you can immediately adapt your supplier network to meet inventory minimums, enable faster decision-making, and meet demands. Thus, companies with integrated digital tools are estimated to be 20% more efficient than their competitors.

Jeff Dobbs, Chair at Diversified Industrials and a partner of KPMG, says that enhanced supply chain visibility can drastically optimize logistical processes. With real-time SCV, companies can expedite their ROIs, lower capital expenses, and manage future risks.

The need for improved visibility tops the list of “most necessary components” for modern supply chains.

IBM noted that real-time intelligence and “actionable recommendations” delivered by AI-empowered solutions can assist companies in reducing the disruption mitigation time from days to hours. This leads to more supply chain visibility and increases the business’s ability to compete on the market.

Supply Chain Visibility Benefits

1. Transparency for Increased Control and Safety

Since supply chains represent an extended network of multiple stakeholders, most processes become inefficient, costly, and face fraud risks. The next-gen technologies such as Big Data, AI, ML, and Blockchain offer top-notch visibility over the entire supply chain.

Tracking the products at each stage of their journey helps identify the links in your supply chain which are most vulnerable and need more protection.

2. Readiness to Respond to Changes and Disruptions

Industry 4.0 forces organizations to embrace intelligent tools. For example, introducing IoT-based real-time tracking tools into the supply chain brings more flexibility for companies. It makes them ready to respond to ever-changing business requirements and market changes at any time.

In accordance with the insights delivered by investmentmonitor.ai, platform supply chains of 2022 should be ready to respond to changes and disruptions not in the manner of “fiscal savings” but via the emphasis on security and restructuring of the supply chain. Rather than implementing temporary fixes, companies are going to think global and consider transforming their supply chain functions to deliver long-term resiliency.

3. Fewer Costs, Fast Service, and Better Performance

Developing supply chain software with enhanced visibility functions enables enterprises to reduce human involvement in many manual operations with data. Automation reduces workforce resources and accelerates shipping services.

For example, tracking RFID tags attached to freight helps to scan these tags at each station. Such accurate shipment monitoring in real-time at all points in the chain gives a competitive advantage without additional risk or expenses. Supercharged with intelligent tools, the non-contact identification systems further guarantee better service and refined logistics.

4. Data Visualization as Top Tool to Handle Sizable Data

Data visualization solutions became highly popular as their market is projected to reach a staggering USD $7.76 billion by 2023, with an increase of 9% per year.

These tools help to view, understand and categorize patterns and tendencies in data. Having the ability to analyze such sizable data sets, supply chain supervisors can make fast and accurate decisions. With the proper techniques for real-time data visualization, supply chain managers should never have to waste time consolidating separate datasets from distributed systems into a spreadsheet.

Best Real-Time Supply Chain Visibility Solutions and Technologies

Visibility tech can have a reverberating effect on supply chains worldwide. While establishing your supply chain IT stack, consider our suggestions to optimize your processes making them more transparent, controllable, and flexible.

ERP Systems

Modern Enterprise Resource Planning (ERP) systems open endless opportunities to make demand planning more visible and controllable through a single platform. Demand streams can be analyzed and categorized to allow systems full control over supply chain business operations, immediate access to critical data, instant updates on inventory, warehouse navigation, and customer orders. Plus, ERP software provides features tailored to your unique business needs so your data dashboards are relevant.

With automated data input and other workflow activities, your employees become more productive and can devote their efforts to valuable business tasks.

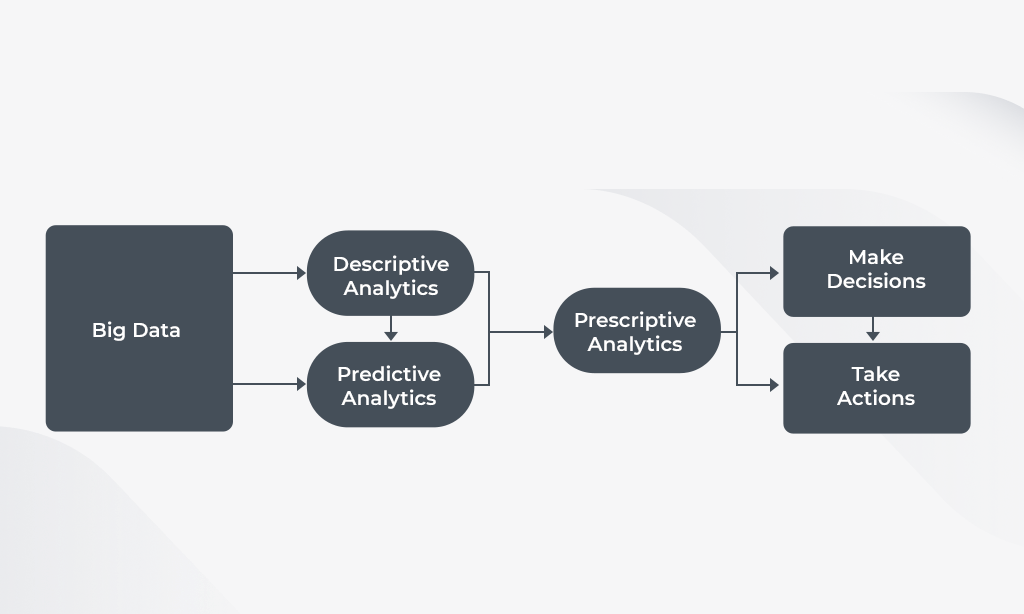

Big Data Analytics (BDA)

Using Big Data Analytics in logistics and supply chain management can completely alter your approach to managing inventory; taking visibility to the next level. Here are some of the benefits BDA can bring:

Excellent Operational Performance

The in-depth operational data monitoring and analysis, along with instant access to this data, can help eliminate multiple bottlenecks.

Better Customer Satisfaction

By analyzing real-time data, supervisors can tailor their warehouse operations to customer requirements, which in turn elevates their customer satisfaction scores. Data analysis can help you to quickly respond to seasonal changes in customer demand, or perform emergency planning to meet new fashion trends.

More Sales and More Gains

Using live data, supply chain financial executives can track and analyze data on a regular basis. Thus, they can track margins with accurate insights to ensure maximum profitability.

More Savings Through Switching to Cloud

When migrating to the cloud, the need for hardware and maintenance expenses can vanish automatically. The SaaS model allows integrating a cloud solution into an existing system to be scalable with minimum cost.

In accordance with the Harvard Business Review, in 2021, businesses invested in big data analytics for gaining new business opportunities via improved operational efficiency (56%), better supply chain visibility (39%), and, hence, improved customer experience (50%).

BDA contributes tol inventory visibility and tackles the challenges of SC disruptions risks mitigation alongside the other solutions for more supply chain visibility.

Artificial Intelligence and Machine Learning

AI and ML are among the most powerful techs used to build a digital supply chain with end-to-end visibility. Of companies surveyed (80%) consider AI and ML as the biggest technologies to overcome complex business challenges across the value chain. Namely, companies see the following benefits once AI and ML are integrated:

- Ability to optimize inventory (51% higher)

- Predictive distribution (45% higher)

- Optimizing distribution networks (42% higher)

Using the tech that analyzes your business and recognizes data relationships that were invisible to the naked eye, and then automatically integrating these insights into your supply chain is driving continuous real-time improvements across entire supply networks.

For example, Bristlecone is a provider of AI-powered apps to help biotech manufacturers achieve visibility into 300,000+ annual shipments. Their smart apps, backed by AI-enabled monitoring of shipments, provide visibility across different locations, carriers, and modes. You can read the full story by the link.

Blockchain

The benefits of using Blockchain continue to emerge, along with the hurdles companies need to face. However, businesses have begun implementations as it becomes easier to connect the different parts and multiple stakeholders. For instance, 64% of company leaders consider Blockchain a current tech objective that will reinvent deeply-rooted industry standards.

Blockchain is an endless source for analytics that aids in risk mitigation and emergency planning. The technology increases traceability, and with the predictive insights it provides, supply chain executives can redirect routes to reduce disruptions caused by unforeseen events.

Application Programming Interface (API)

Businesses are replacing cumbersome EDIs (electronic data interchange) with efficient APIs (application program interfaces). Supply chains are faster, more efficient, and can be backed up by data insights with APIs. The technology enables transferring data from one system to another, giving access to this data from a central location and helping procurement managers make data-driven decisions.

- Along with better visibility, API-based networks provide even more benefits:

- Faster interaction between shippers, carriers, and 3PL providers in terms of document management and payments

- Instant access to information about shipping rates

- Automated matching of freight and transportation modes and routes

- APIs provide a new level of customization allowing for more flexibility

Summary: Developing Supply Chain Visibility with Innovecs

Developing a responsive supply chain is essential to overcoming complex enterprise challenges in the manufacturing, retail, and e-commerce industries. Introducing management strategies across a vast network means companies are often playing catch-up with planning and production hurdles.

A live supply chain provides greater transparency into a company’s inbound/outbound processes, enabling it to trace daily activities. This includes route planning and transportation, warehouse, and inventory management systems (TMS/WMS/IMS).

At Innovecs, we have completed several international projects to develop dedicated Supply Chain Visibility (SCV) software for both startups and small-to-medium enterprises (SMEs). Our SCV solutions helped businesses build a secure and transparent supply chain that facilitates processes quickly and cost-effectively. Please reach out any time you see the need for increased visibility in your supply chain.