As Easy as Pushing a Button? The What’s Why’s and How’s of RPA in Supply Chain

In an era of new technology breakthroughs, Robotic Process Automation (RPA) has established itself as a helpful component of almost any tech-reliant industry. As a natural byproduct, RPA in supply chain world is becoming the new norm.

We know RPA is happening all around us, but what does that mean? All that’s left to grasp are the what’s, why’s, and how’s of Robotic Process Automation.

According to Robotic Process Automation Market Size Report, the global RPA market is expected to grow at a compound annual growth rate of 32.8% from 2021 to 2028. Let’s get you up to date before you miss the boat.

What is Robotic Process Automation?

At its core, robotic process automation is pretty self-explanatory. It is the giving over of certain menial tasks to specific programs – i.e. robots. The tasks in question are generally repetitive and continuous, which means that the installation of one robot is usually capable of securing a steady flow of one particular process. However, there can be exceptions. As technology marches on, and businesses get more confident with RPA, software gets more complicated and personalized. With this, opportunities to streamline even more segments of work arise.

To clarify, robotic process automation is not the same as robotics. While robotics deals with actual machines in the physical world, RPA deals with software, and its “robots” are programs. Thus, they are different from the usual associations with the term “robot.”

Aside from its meaning and purpose, in the public eye automation is frequently tied to certain concerns and even superstitions. Thus, in order to move forward with what RPA is, one needs to know what it is not.

What RPA Is Not: Myths and Misconceptions to Overcome

The normalization of robotic process automation is a relatively new process, but suspicions about over-reliance on technology have been around for decades. As a result, RPA in the supply chain can look rather intimidating to even seasoned professionals. Up-and-coming companies whose knowledge of RPA stems not from research, but word-of-mouth and “myths.”

Here we address such fears:

- RPA pushes people out of jobs. The public fear that machines are here to replace us goes way back to the roots of the sci-fi genre. But today’s tech fears have no legs to stand on outside of science fiction. In reality, robots do not steal jobs – they only take on the most repetitive and boring parts. A joint study by Forrester Research and UiPath has determined that the use of RPA increases employee engagement by 57% and skyrockets employee efficiency by 86% all the while decreasing manual effort by 71%.

- RPA costs too much to implement. While the initial installment of the software definitely has a price tag, businesses should look one step ahead at the inevitable return on investment. A robot handles menial tasks faster than an average worker, can operate longer hours, and is completely devoid of human error and/or learning curve. The payment is temporary – the benefits are forever.

- RPA cannot handle complicated tasks. While the most common way to use RPA is for simple monkey-see-monkey-do errands, modern technology already offers more nuanced applications. If a company wants to take the next step, intelligent automation – a combination of RPA and AI – can be used to handle complex processes from end-to-end.

The Pros and Cons of Robotic Process Automation

The introduction of RPA has its advantages, as well as aspects that need to be treated with care, lest they turn into drawbacks. Just like with any other transformative process, a company embarking on its RPA quest should be aware of both.

The pluses include speed, consistency, security, and, as a result, increased productivity. What a human worker cannot do – a robot can. This technology ensures practically faultless and easy streamlining of your operations, with interfaces of RPA software being notoriously user-friendly. In addition, robots can help your business save money. According to the Institute for Robotic Process Automation, RPA can bring your average costs down by 50%.

The minuses boil down to the initial investment, software upkeep & management, and employee hesitation. Indeed, the courage needed to transform your processes to fit a piece of RPA software is a leap of faith. But this is a necessary step all businesses who are willing to automate need to take at some point. The software also requires regular checkups and updates, and staff to understand how to complete these tasks. The latter means a bit of a learning curve for the average employee who needs time to adapt, or it means hiring new people altogether.

Advantages of Robotic Process Automation in Supply Chain

The logistics industry is no stranger to robotic process automation. In fact, McKinsey Global Institute forecasts that adoption of artificial intelligence and RPA in supply chain solutions promises around $13T (that’s a capital “T”) in GDP by 2030 (which is 16% more than today).

It follows that while the pros and cons of general RPA are applicable to the supply chain, there are also some specific logistics-oriented benefits that the industry can get out of the new technology.

Supply and Demand Planning

Robots can automatically collect and sort through data from orders and deliveries, providing a company with valuable information on its patterns. This information can later be used to prognose the demand for certain goods. With such insight applied to planning, the chances of understocking or overstocking diminish, saving a company time, money, and storage space.

Order and Delivery Management

Automation can streamline the ordering process or take on administrative tasks that are similar in nature. For example, a payment process could be improved by installing RPA. By connecting a logistics company to its clients by an automated banking system, they can get a quick and trackable way to process transactions.

Use cases of RPA in supply chain are becoming widespread. This year, Direct Expedite achieved 80% faster response times and 100% accuracy! All because they implemented robotic automation for order management. Here is a comment.

The utility of robotic process automation in a supply chain does not stop there. Automation can follow an order to the delivery stage, assigning a partner from a database, and making the entire journey from point A to point B visible in real-time.

Warehouse Management

Riding the coattails of predictive management are Warehouse Management Systems (WMS) and Inventory Management Systems (IMS).

A classic example of robotic process automation in supply chain management, WMS handles all of the processes happening inside of a warehouse; be it task management, design, scheduling, pick & pack, fulfillment, and more.

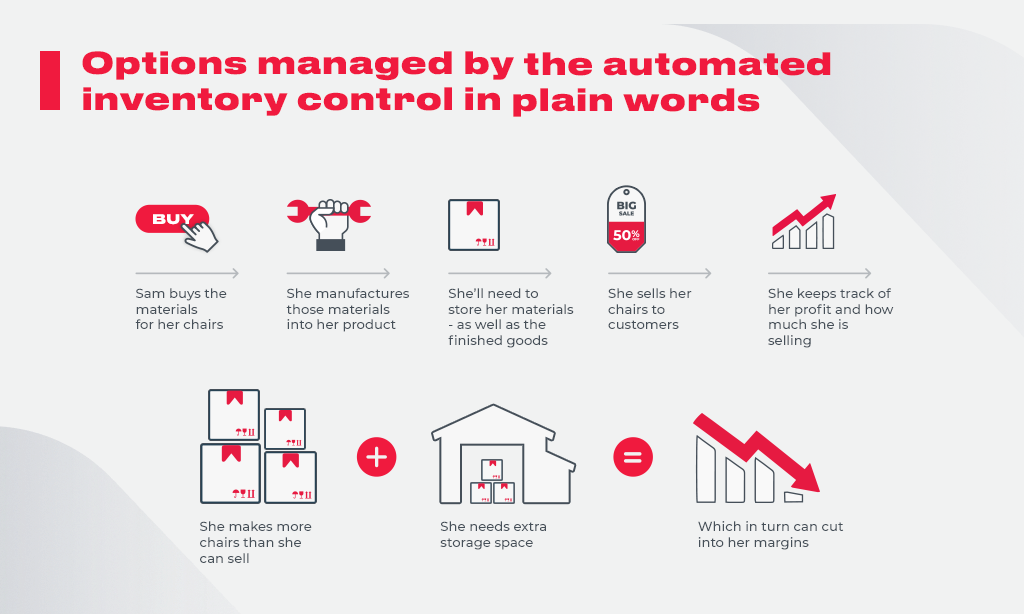

An IMS is a more specific multi-purpose tool inside of WMS, aiming to increase control and visibility over stock. Inventory control systems are highly personalized. Taking into consideration specific goods and the conditions necessary for their upkeep, they provide you with 24/7 access to data on stockages, profits, sales trends, potential discrepancies, and more.

How to Implement Robotic Process Automation in Supply Chain

Rome was not built in a day, but the end result was worth it. In a similar fashion, if a company decides to implement RPA efficiently – that, too, will require time, and no small amount of planning. But do not be overwhelmed – we will walk you through the four mandatory stages of an RPA journey.

Planning and Assessing

The questions most asked:

- Which supply chain processes will benefit from RPA the most?

- What is more sufficient: implementation with an in-house team or through outsourcing?

- What infrastructure will be used to host the RPA for the supply chain?

- What additional tools will my business require to be fully compatible?

- How will my employees be introduced and adjusted to this new technology?

These questions cover the bare-bones structure of the planning stages, and are meant to expand and branch out, ultimately painting a SWOT analysis. Afterward, technical and functional teams need to work together. Followed by a good brainstorming session about the tools and vendors necessary to install the best type of supply chain RPA to fit your needs. After a thorough assessment, the end-product of planning and assessing brings us to this shortlist of necessities.

Development

Just like any other piece of software, RPA in a supply chain needs to complete this software product development life cycle:

- Requirements Development

- Prototype Development

- High-level design

- Detailed design & development

- Alpha testing

- Beta testing

- User acceptance testing

- Product release

The development stages cover the first four points where the specifics of RPA, secured in planning and assessing, become reality. At this stage, the result is an end-to-end production of RPA itself. When workflows of automation, along with its expected results, are set in stone it’s time to move onto the next stage.

Testing & Deployment

Here we start alpha testing, beta testing, user acceptance testing, and product release. For better digestibility, they can be boiled down to three steps:

- Quality Assurance. The robots need to be tested early on. This includes not only performance checkups but their compatibility with other software. The platform on which they are hosted and their ability to be scaled later on is especially important: a 2019 Forrester report shows that over 50% of RPA projects cannot expand beyond 10 bots, and over 70% stall before reaching 50.

- Communication. It is imperative to ensure that the rest of your business units understand the upcoming change, and specialists closest to the “robotized” processes possess the right skills to run the software.

- Vigilant deployment. The moment of launch marks the end of preparations and starts the period of strategic observation. The first few days of an RPA’s full functionality are the times to see how it affects your operations and to address any issues that might arise.

Support and Maintenance

Once the RPA becomes a natural part of your supply chain, it is necessary to ensure steady updates. Keep your security measures fresh and work to scale for the future. In addition, the teams managing the programs should be accustomed to working in an agile environment.

Your RPA software, even perfectly crafted, does not exist in a vacuum. It is crucial to remember that if the installed “bots” are connected to numerous systems, new changes in any of these systems will inevitably affect the bots. Fixes and alterations are inevitable, but if you are ready, so are the profits.

Start Your Journey into RPA for Supply Chain Management with Innovecs

Robotic process automation in supply chain management is the swiss army knife of solutions. You can expect increased control, prognoses of the future based on real-time data, and management of tasks, orders, deliveries, and inventory. It takes boring errands out of your workers’ hands and saves you money and time in the process. It can evolve and expand at your command.

Innovecs is here to help! We can develop and implement all or any elements of your RPA system. Having a decade of expertise in the areas of artificial intelligence, machine learning, and cloud solutions we can handle any project or segment of your automation phase.

We are agile, understanding, and accustomed to international collaboration with our global clients. Feel free to explore some of our success stories and see if they fit with your business model.