Automated Inventory Management System: How It Works To Enhance Your Business

An automated inventory management system contributes greatly to business digitalization, leading to increased system accuracy, the tuning of real-time tracking, early problem detection, and increased efficiency. Obviously, an automated inventory system is able to grant new possibilities to your business.

Either you are an e-commerce executive, small, medium, or perhaps a fortune-level supply chain business owner. You might even have deep roots in logistics. If so, that’s great news!

Going digital and optimizing and streamlining your inventory management will increase bottom-line ROI. Moreover, it will free up cash flow to invest in the latest and greatest emerging tech. We can help support those efforts, but first, let’s take a look at an automated inventory management system works

Inventory management software is transforming modern industry tremendously. This statement is reflected in the iGeeks Blog, which defines stock management as “one of the primary aspects” of modern business trends. Meili Robots proves this fact with a substantial 22% growth rate in the e-commerce global robotics market in 2023.

A lot of digital transformation companies provide a variety of automated inventory management systems to optimize business scalability, address human error issues, save time, and, as a result, gain cost-effective company operations.

What Is Automated Inventory Management?

How can you reach a smoother performance of supply chain business processes? Regarding inventory, automation is defined as utilizing certain software or technology to manage warehouse stock in real-time with minimum effort and errors. This sophisticated method grants new possibilities in:

- processing customer order deliveries;

- inventory demand fulfillment;

- managing real-time data, which is essential for warehouse operations;

- comprising all the warehouse management systems already applied;

- performing tracking tasks.

DHL in its blog notes an automated inventory management system as a solution for enhanced warehouse visibility and control which provides very wide opportunities for businesses.

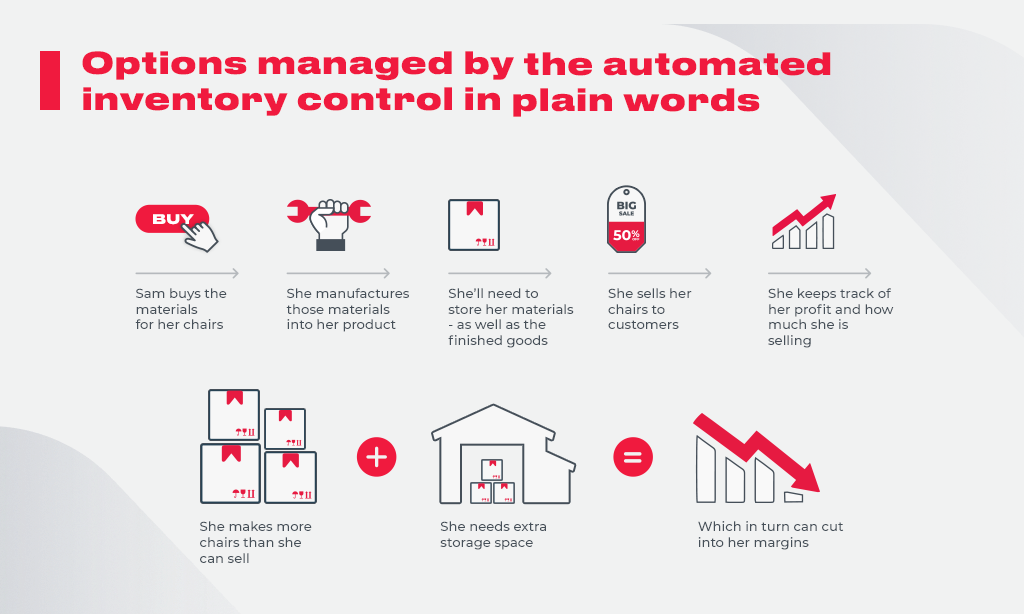

Inventory automation includes many options. Among the most widespread ones used by the retailers is automated reordering; keeping accurate track records of stock transferring; uniting multiple locations reporting in your chain; processing store orders; notifying about the goods dispatch.

These and other options give opportunities to address operational cases when workers manually log each item into the inventory system and errors occur as well as visually inspect products’ quality and quantity. Intel reports 5% of inventory inaccuracy only due to manual processing. However, other problems exist as well to be solved by digitalizing business operations. That is why utilizing inventory management software grants the potential to the whole business to perform better.

Inventory Types And How They Are Automated By The Inventory Control Systems

To learn more details about automated inventory control systems it seems reasonable to identify core inventory types, and then categorize inventory control systems assisting in their management. Mainly inventory is grouped into:

- raw materials as components for the production of the finished goods;

- finished goods as the products ready for selling;

- MRO (maintenance, repair, operating supplies) stands for everything supporting the manufacturing process. What’s interesting is that the screws, for example, used for machinery assembling are classified as raw materials, but when they are the spare parts for machinery repairing, they are grouped like MRO;

- work-in-progress inventory items, which are the goods waiting for the next stage of processing having been produced (e.g. goods placed in the stock for quality control)

Camcode, an asset tracking expert on the market, uses the concepts of perpetual and periodic inventory control systems. Perpetual control apps update information about the stock in real-time via barcodes and special scanning equipment. Periodic ones utilize manual item counting and number comparing in the beginning and in the end of the period. Once a company applies a perpetual system to count on MRO or raw materials, it needs special equipment; but when it uses a periodic control system, it should consider counting errors and time limits to provide the sales department with accurate information.

If we try to explain the very process of inventory control, it could look like that in the picture below.

Two effective ways of inventory management

What ways of warehouse automation are helpful to manage inventory better? Barcode or RFID systems are the two most common tools that are able to improve real-time inventory management effectively.

Barcode is a visually represented picture available to be read by special scanners and giving the possibility to process inventory data quickly with no burden of the documents and manual counting. This way of warehouse automation minimizes human errors and simplifies the stock records process.

Radio-frequency identification (RFID) stands for recording crucial product data in smart labels, and this technology has several advantages in comparison with barcode systems. It can be performed off-site and RFID tags can be reused in comparison with the possibility of barcode optical scanners usage.

Thus, for example, the Intel RFID sensor platform (RSP) is reported to increase warehouse visibility, perform high “dock-to-stock” outcomes (the goods are always ready and available for delivery) as well as smoothen the return-flow warehouse processes (special Intel RSP technology to track the movements of the boxes around premises).

Both solutions enhance warehouse control greatly. They are part and parcel of inventory control workflow which includes the following key stages helpful in managing stock effectively:

- items design (on this stage one needs to know the demand for the product);

- purchase order creation;

- goods delivery;

- purchased products return;

- reordering.

In your plant, factory, or delivery warehouse, these processes are automated with the help of software using robotics or IoT technologies, and it can be said a digital transformation strategy is being implemented. And here a lot of technologies come in handy such as cloud computing, AI and data analytics, easy access to on-demand warehousing techniques, modernized tracking operations in real-time mode, and interoperability between all the key warehouse software to make automated stock function smoothly.

How to Introduce a Digital Transformation Strategy Effectively Via Inventory Management Automation

Automated inventory management systems are crucial benchmarks of company digitalization. Nowadays, it’s not a trendy feature but a constant necessity if a company is expected to compete in the market.

According to Gartner, 91% of companies are going digital nowadays, 87% of top management representatives stress the necessity of digitalization, and 51% of successful digital transformation cases are prompted by the market needs and necessities rather than by inner company wishes. These figures provide strong evidence of digital transformation’s crucial importance.

What Is Digital Transformation Strategy

Forbes describes complex digital changes via several concepts:

- digitizing as a process of transmitting all the substantial assets into digital format (e.g. use only scanned documents stored in the clouds);

- digitalizing as a stage of using special software to make separated company processes digital (e.g. using SAP to perform a variety of transactions with the vendors neglecting paper documents flow);

- digital transformation is a series of overall company changes as a result of the completed two previous stages. More details about digital transformation is here, in our blog.

Considering this view we can say that Ukrainian Boryspil Airport is a digitilized company because of its digital document flow or baggage accounting software used, but they are not going totally digital like Amazon cause many operations are still performed manually (e.g. aviation security checks, lost luggage claim procedure).

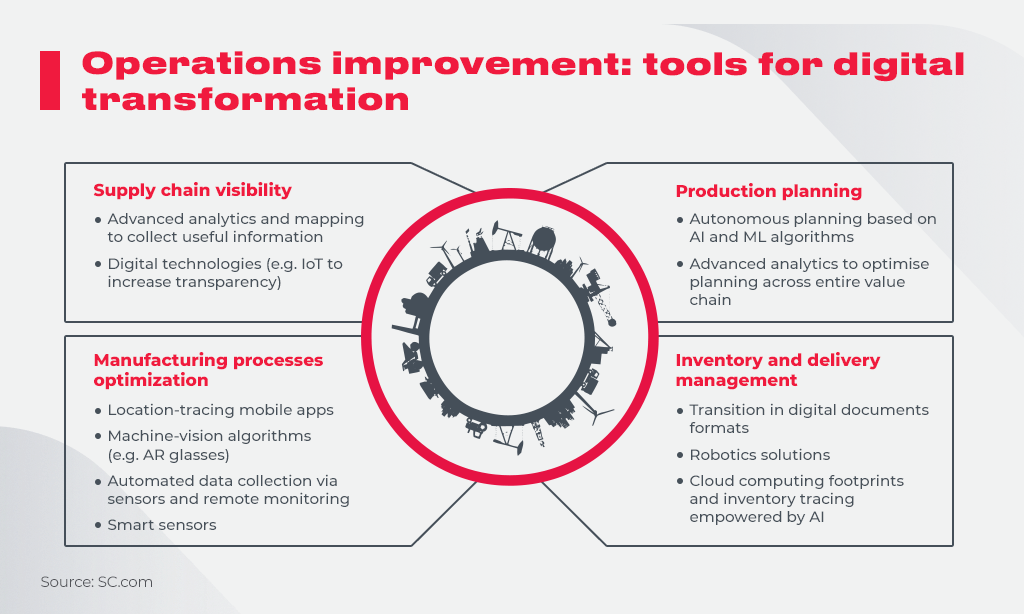

If we look at the viewpoint provided by the Standard Chartered web resource depicted below it comes to say: main issues of the overall digital change are connected with the inventory automation to a great extent.

According to the Prophet review, 67% of business respondents utilize digital tools to enhance supply chain visibility, efficiency, and smoothness. And Integrated supply chain option development can add really great value.

Middle-sized corporations consider automated warehousing takes 67% of digital transformation success whereas, for example, payment transaction optimization stands only for 27% of high performance or 47% of workforce collaboration introduced. Reading these facts we can judge digital transformation is empowered greatly by automated inventory management.

Outstanding Examples of Automated Warehouse

The above statistics are proved by numerous outstanding examples of the market leaders’ development. Thus, practically everybody has heard that Amazon gives people what they want ASAP through its “one-day delivery” concept. The company has launched a “super smart army of slaves” (bright IoT technology example), and applied deep learning, and AI.

In 2020 with the whole world suffering a pandemic situation, Amazon reported $350 billion in annual revenue due to their established smart warehouses empowered with outstanding technology of automated inventory management. They have shortened the way from customers’ wish of buying the product to ordering it via Alexa smart devices and drone delivery asap.

SC.com honors Walmart and Coca-Cola as the leaders of warehouse automation. Walmart introduced the robots driving among the stock aisles to speed up the pick and pack processes. Coca-Cola’s stock houses 25,244 pallet locations and they address complicated and expensive delivery tasks from the off-site to regional locations via FKI smart logistics solution of on-site storage forecasting the demand and foreseeing future market expansion.

The Industrial Distribution Twitter account illustrates successful warehouse automation cases with DHL examples stressing this kind of automation as “making sense and focused on ROI.” DHL deals successfully with medical implant deliveries for next-day surgeries when speed and error zero levels are of significant importance. They employed the Locus Robotics solution and reached reduced cycle time with two times more productivity.

Following these successful cases, it becomes clear that inventory and warehouse automation helps to cover all the processes comprising order, receipt, inventory maintenance, reporting, billing, premises zones assignment, and share.

Trends to Watch in Inventory Management Automation

FinanceOnline.com, a popular reviewer of financial products, shared its vision of 2023 supply chain development trends. They mention that outsourcing has become a real boom: we’ll observe 42% of outsourced services in distribution and logistics, 37% in manufacturing, and 23% in packaging.

“Inventory management automation is still getting a burning priority,” reported in the article, where they outlined the most popular technologies for automation. Among them are Data Analysis, IoT, and Cloud Computing as the TOP 3 for tackling future challenges in 2023.

Except for advanced data analytics, IoT, and cloud computing, we’ll see the increased priority of info security, and predictive analytics in inventory management automation.

Any prioritized technology of the future is aimed at making warehouse operations smooth, efficient, and less time-consuming. The more technologies you’ll involve in your warehouse management, the more satisfied customers you’ll gain raising the ROI, and review.

We are proud enough that Innovecs as a software development company has got deep expertise in the development of automated inventory solutions. Here is one vivid example of how WMS rebuilding improves the whole business performance.

We’ve been collaborating with the US Cold Storage company to tackle the problem of poor WMS stability and the necessity to renew the codebase to increase its performance. It was more than 2 million lines of code written, eight times deployment speed increased, and custom features integrated in accordance with the client’s requirements.

Collaboration has been ongoing for years. Starting with the challenge of migrating a legacy IBM DB2 database to Oracle, Innovecs’ professional team made numerous warehouse launches possible.

Cloud migration took half a year, which is “the shortest time possible for such company size migration,” – according to Anton Shashuk, Innovecs’ Delivery Manager. Since the cloud migration completion, Innovecs’ experts maintain the database and run applications leveraging Oracle cloud solutions.

Innovecs, in collaboration with US Cold, chose Oracle, because:

- It’s both a multi-model database management system and a platform for cloud services.

- It allows running applications in a highly-available, consistently high-performance environment.

- It’s a secure system operation, and Oracle cloud support is available for managing service or change requests if needed.

Innovecs shared its cloud expertise in collaboration with US Cold Storage for:

- Business scaling: multiple warehouse launches leveraging Cloud migration.

- Operational efficiency boost: migrating the database and applications from DB2 to Oracle granted huge potential for secure infrastructure functioning.

- Fruitful decision-making: our certified cloud experts shared the necessary knowledge with the US Cold Team.

Joshua Holi, EWM Implementation manager at US Cold, emphasizes that “it takes quite a short period of time till a complexly reviewed WMS system starts to function” on all the company locations being user-friendly and totally intuitive.

He notes they appreciate Innovecs’ client’s care with the possibility to visit the company on-site to be aware of options to be fixed. This close collaboration granted a smoothly functioning rebuild of automated warehouse management systems.

Bottom Line Facts

Having read 2021 statistics about the market necessity to implement warehouse automation and market leaders’ cases of fully streamlined warehousing and the outcomes they got due to the introduction of new technologies, one can conclude that an automated inventory system has vast opportunities to enhance your business revenue via:

- wide coverage (special software deployed on site is able to cover many processes starting from ordering and leading to the delivery);

- timely events capture (either it’s a process of the goods counting or return claims);

- eliminating manual operations throughout the whole inventory maintenance process;

- high accuracy and speed up the processing time.

We guided you through understanding what digital transformation is and forming the vision that automated inventory took 67% of the success in the process of going digital for the company. We illustrated cases of Amazon robotics implementation, Coca-Cola logistics solution for on-site storage, and DHL tremendously smart delivery performance for medical surgery implants.

All the mentioned examples became true thanks to new technologies such as AI, cloud computing, and data analytics as well as digital tools implementation such as RFID or barcode scanners.

Either you decide to outsource your inventory management automated system or develop a custom one, such a company as Innovecs is able to advise on better launching, support, and fixing the bugs. For this reason, it’s just enough to contact us and order a consultancy.

In case you are willing to get more useful information in the field of logistics, we’d like to introduce the next episode of “Rock Your Supply Chain: Evolution of TMS” on August 25, 2022, at 11 am EDT (5 pm CEST). Join our discussion with the dedicated panelists from FreightTech:

- Michele Pelino, Forrester, Principal Analyst

- Ron Richardson, Turvo, Chief Revenue Officer

- Ryan Schreiber, Metafora, Vice President, Industry & Growth

Webcast host Michael Beelar, Innovecs’ VP of Supply Chain and Logistics, together with the industry leads and experts will uncover the latest trends in technology concerning supply chain.

Join us and get insights to boost your business in logistics or make a real promotion in your FreightTech career.