Supply Chain Planning Software to Reduce Logistics Risks and Boost Profits

If a business is aiming to grow in 2022, it’s high time to use advanced supply chain tech solutions to design an agile supply chain to manage inventory, tune deliveries, and have more power to compete with other market leaders.

- The focus on more control in supply chain planning targets:

- localizing the supply chain elements for better visibility;

- utilizing multiple logistic partners for more agility;

- more actively dealing with the last-mile delivery solutions to boost SCP productivity.

Supply chain planning (SCP) software helps to manage and optimize costs, prevent delayed shipments or logistics errors, support customer service, and communication, and help forecasting and decision-making. All these features are possible due to the logistics software solutions that assist businesses to operate under a complicated pandemic and highly competitive modern environment.

Procurementtactics.com forecasts that the global supply chain market value will increase from $15.85 billion in 2019 to $37.41 billion in 2027. The blog went on to explain that these figures were greatly influenced by the “internet penetration, emerging retail markets growth, and a variety of benefits” SCP software presents to businesses.

We decided to shed some light in our blog on how technologies implemented in certain software solutions can assist your business in designing effective supply chain planning for increased revenue.

What Is Supply Chain Planning

TechTarget papers distinguish that SCP is a part of SCM alongside supply chain execution (SCE). For a living example of supply chain planning, Willy Shih, a professor of Management Practice at Harvard Business School, spent 28 years in the logistics industry and presented examples of what a supply chain is and what the basic mistakes of supply chain planning are.

This presentation was given in the TEDx Talks format with the funny slogan: “What Toilet Paper Can Teach Us About Supply Chain Planning.” In the video, he talks about observing people hoarding toilet paper early in the pandemic, and decided to use it as an example of what product features we consider during SCP implementation:

- price (it influences the amount of procurement and finance needed);

- whether it takes much space to store the product (“is it bulky to ship”);

- how tradable the product is (he explains toilet paper is not worth delivering all around the world, so its tradability is not high);

- whether the major markets are closed by domestic manufacturers;

- whether the factory changes its capacity seasonally while producing a certain product (he specifies that toilet paper is demanded at the same level every season).

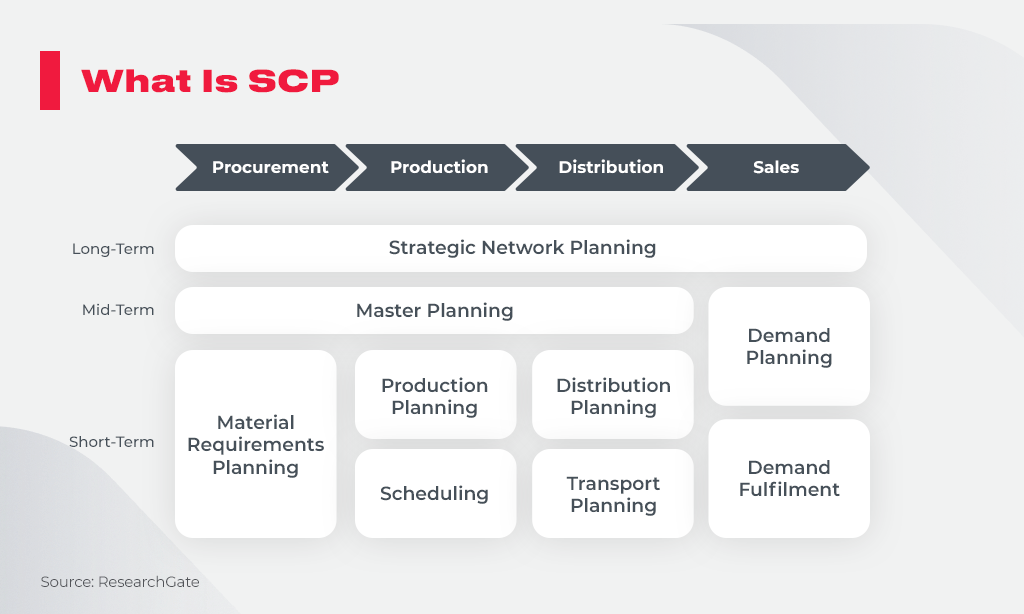

This example demonstrates that supply chain planning is a process to consider all the product features, forecast its shipment costs, and foresee the demand to manage procurement. Gartner proposes a more sophisticated definition: SCP is a set of actions aimed at assets managing to deliver the goods or services from supplier to customer.

On each SCP stage depicted above, technology can cover repetitive, time-consuming, or dangerous tasks. In its blog, Forbes provides a good example of SCP of steel beams: “Imagine you might delegate your employee to conduct the physical stock of the beams to forecast raw materials procurement, to foresee the store space needed or calculate how much you need to deliver. Each action is risky, dangerous, and can not be 100% accurate.”

Here, AI and big data come in handy: AI performs predictive analysis, which is helpful to count how many beams to produce, and distribute (when and wherein the nearest months), and which ways of distribution will be the most efficient. That is the objective SCP systems are designed for.

Supply Chain Planning Systems: How to Achieve Connected SCP

Connected SCP from start to the end-user is valuable and critical to succeed in a highly competitive market. Anaplan, a cloud platform for agile financial and operational planning, emphasizes in its blog that really efficient supply chain planning system should cope with the following operations:

- dealing with not only the historical data but forecasting via “what-if” scenarios;

- synchronizing SCP with the whole enterprise planning to consider global company processes and their influence on supply-demand balance;

- forecasting the end-user demand, counting not only previous data but also analyzing current customers’ demand signals;

- apply real-time data across the whole supply chain planning elements.

Due to a wisely built supply chain planning system, the company is able to consider every possible future obstacle for the elements of SCP.

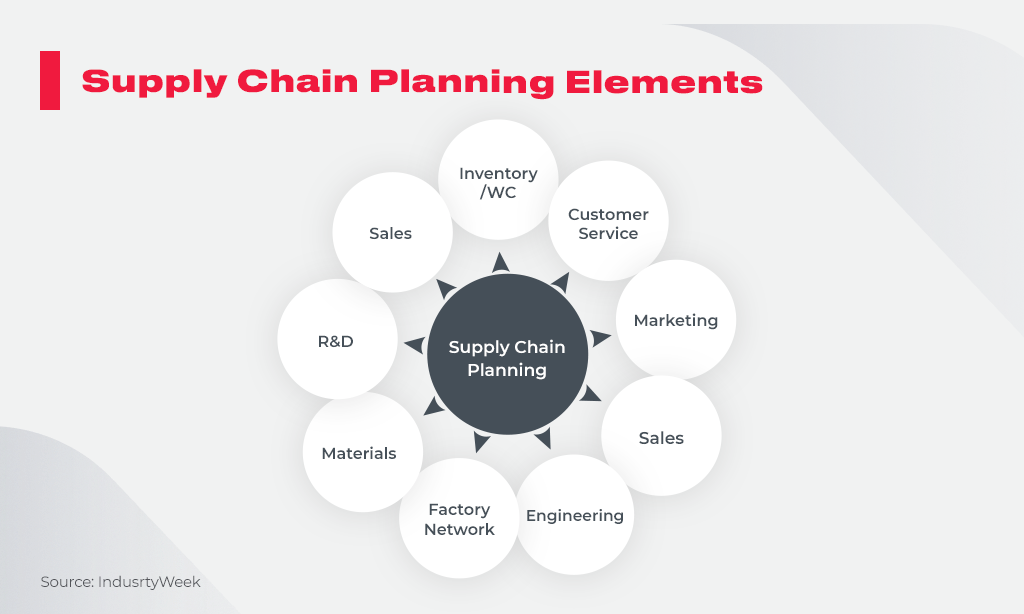

Supply Chain Planning Elements

The supply chain may differ in its specific components, but to imagine what elements should be regulated and managed while SCP, it’s worth distinguishing the following ones:

- supply chain operations: production, providing information about current inventories, and demand forecasting (every operation involves different data and departments—an efficient SCP system should unite all of them and create smooth cooperation);

- purchasing: keeping track of the raw materials suppliers, spare parts vendors, or services necessary for production;

- distribution: products shipments, returns processing, or client service communications.

Element classifications may vary, but the core issue is that before taking any steps in designing SCP software, a detailed company supply chain operations profile is worth creating to consider every element and arrange its automated functioning.

Each element of the supply chain is powerful enough to influence the overall success of a business. Innovecs has deep expertise in logistics: we can collaborate with you to enable every SCP element:

- integration: collection of accurate data about deliveries in one place for data analysis, allowing for quick and efficient decision-making;

- operation: we can develop the software to align your supply chain operations with the rest of your business for more agility;

- procurement tuning: comparing producers and demand forecasting will give a better experience in planning your supply chain;

- Innovecs proposes high-tech solutions for centralizing the delivery and returns processes for real-time management and SC visibility.

Supply Chain Planning Solutions and Their Benefits

DHL, a world-leading provider of supply chain solutions, specifies in its brochure a variety of supply chain planning elements and processes worth considering for effective business operations.

Any supply chain planning system should take into account all the tiny processes present in the modern company supply chain: from warehouse management to customer demand forecasting. Once you’ve decided to boost the profitability of your company and outsource custom SCP, it’s worth thinking of the following issues to be presented in the developed custom software:

- purchase management;

- end-to-end supply chain visibility (user-friendly interface allows easy data access from every company location);

- documentation processing throughout the company (design a single point of contact for all the supply chain participants);

- performance reporting and forecasting.

These features target several added value options, such as real-time data generation, supply chain flow mapping, estimation of future possibilities to broaden the supply chain, and pushing SCP system updates to generate more value for the company management.

Wisely tailored SCP software gives a variety of benefits that prompt quicker ROI and higher revenues due to:

- costs decreasing as a result of improved inventory management, storage space optimization, and optimized SCP system responsiveness;

- better quality of collaboration and communication between the supply chain participants;

- more efficiency: possibility to adjust dynamic changes in supply and demand;

- higher profits;

- eliminating delays;

- stock auditing and waste reduction to become a more sustainable business.

All the information above is helpful in reaching SC’s increased supply chain efficiency, better analytics (every supply chain process results in data businesses must deal with), reduced costs, and risk mitigation.

The core vision for the power of supply chain planning is in boosting supply chain compliance for more business sustainability. The more suitable to the standards your raw materials will be, the better you will meet international goods standards, so you’ll cut return costs, preserve, and make your brand reputation more robust.

Proper SCP software grants the ability to build in the compliance benchmarks and check for more supply chain visibility, as well as a reduction in human errors, resulting in cost reductions.

Overall Glimpses: Importance of Supply Chain Planning

Supply chain planning as a forwarded process of balancing supply chain components (purchasing, production, storage, delivery) is quite complicated. Thus, for example, demand planning involves many departments, and they should agree on many issues: inventory strategy, managing constraints, and optimizing supply chain wastes. Here the SCP system comes in handy to automate data processing, forecasting and making shipping decisions.

It doesn’t matter whether a business owner decides to apply ready-made cloud solutions for SCP or design custom software to manage the supply chain to produce and deliver the product to the final users, here are core offerings worth considering for better performance:

Jabil, an electronic services provider, outlines SCP systems creation, which involves an easy-to-use system with a high level of data visualization available for all the network participants:

“Any SCP system would rather visualize information to involve every participant of the supply chain in data observation and decision-making.”

Innovecs is a global digital transformation tech company that provides customized logistics solutions, including:

-

- supply chain planning modules based on data collected from various sources;

- better reporting and analytical tools;

- high-tech tracking systems;

- tools for warehouses automation;

- saved shipping time and cut delivery costs.

In the list above, the main elements and stages of any SCP are described. Business owners can use this checklist to optimize their supply chain planning via custom software. Once you see the potential of your business growth and scaling in proper SCP, you are welcome to contact us for a more detailed consultation.