Supply chain management solutions: how to streamline operations from start to end

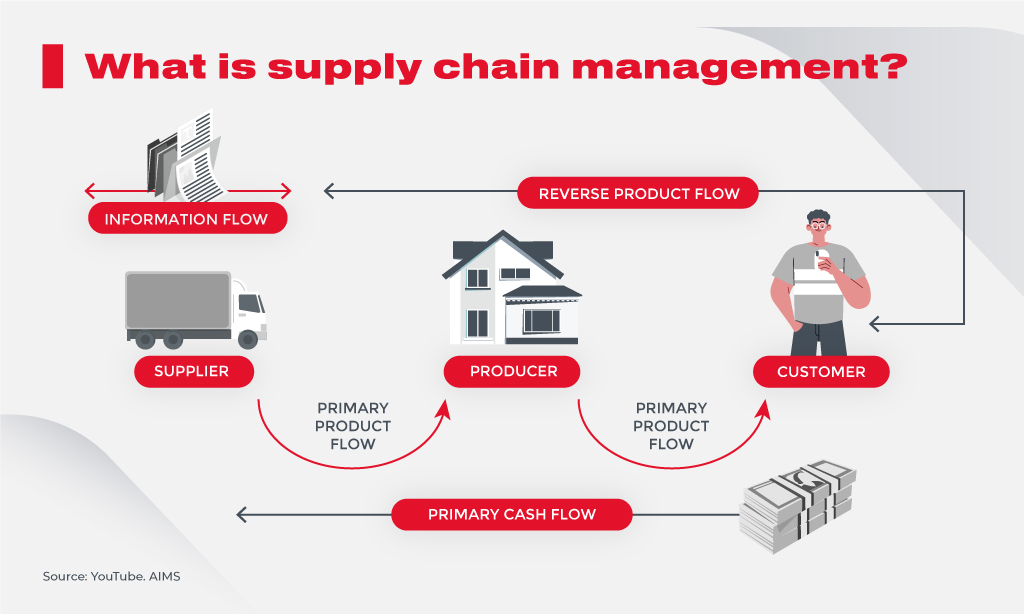

Supply chain management solutions lead you to business benefits via integrating and synchronizing all physical, financial, and information flows that a company needs to fulfill.

If you’ve already thought about streamlining the operations to reduce costs, increase business efficiency, keep up with the demand better or improve risk mitigation, SCM management solutions are surely for you.

Forbes analyzed the “4 Ps of the supply chain management crises” in 2022:

- Products availability will be complicated

- Prices of the suppliers will still become higher

- People with the necessary talents will be difficult to obtain (especially STEM skilled, which is valuable for modern industries)

- Political decisions will have a huge impact on the global supply chains

IBM shared five components of the supply chain a business owner should focus on to optimize for better performance (planning, sourcing, manufacturing, delivery, and returning). DHL spoke about integrated supply chain solutions to streamline operations from start to end. They stress the necessity of “gaining operational visibility,” the introduction of innovative analysis tools for better business insights.

The tips mentioned above are invaluable for supply chain management, your business digital transformation, and advanced planning. But what is also crucial is to know the market of SCM management tools in detail to prevent possible disruptions in the global supply chain that will cost a fortune.

In this blog, you will find the overall supply chain components profile, 2022 trends glimpses in SCM solutions, and a precise overview of how it’s possible to streamline the supply chain processes integrating them fully and efficiently into the existing SC network.

What is supply chain management and the value of innovation in it?

Gartner emphasized that both the company and its value chain partners are involved in “orchestrating physical assets and information flows” for smoother demand fulfillment. The key objectives of the supply chain management are:

- Coordinating and arranging all the business processes (from procurement to returns)

- Planning resources and capacities to meet the customers’ needs

- Transportation (both inbound and outbound) management

- Tuning the warehousing and distribution to balance the “supply and demand” system

- Manufacturing management (if production included in the organizational scope)

- Controlling and optimizing store operations and servicing

The role of SCM

Simon Ellis in “The Path to a Thinking Supply Chain” four years ago predicted the key role of five Cs for future supply chain management: connected (IoT for better data structure and access), collaborative (cloud-based networks for better collaboration among the suppliers), cyber-aware (protected from hacks and attacks), cognitively enabled (AI platforms as SC control towers), and comprehensive (analytics utilization).

Nowadays, in accordance with IBM research, those innovators who took advantage of the above-mentioned tips report 34% revenue growth and 326% more profitability than their peers. Moreover, companies, which innovate harder (e.g., investing 30% more in AI and self-learning software), expect 53% more ROI in comparison with those, who invest fewer resources.

They explain that economic activities and business results can suffer once the supply chain faults appear. And efficient supply management innovations are the only way to perform well in delivering the right goods and services to the right customers via a network of linked and coordinated activities.

SCM contribution to business success

Innovecs, as a global digital transformation tech company, is sure that business intelligence and digitalization are powerful forces contributing greatly to your business success. We deal with the clients to build up the value of a digital supply network and observe how this empowers:

- enhanced connectivity (join suppliers, vendors, and partners efficiently);

- maximum visibility (clear view of inventory and delivery processes);

- data-driven decisions via AI-powered analytic tools;

- improved customer experience; and

- efficient supply planning and forecasting.

You can rebuild your warehouse management system, optimize the trading platform, or introduce supply chain management tools globally throughout the company. Any option is a great contribution to business success via tuning the processes and efficient data processing, improving the reactions to any SC disruptions.

2022 trends in supply chain management

2022 is bringing a new vision of the implementation of supply chain management solutions for businesses. You can hear the same wording such as “omnichannel distribution” or “AI-powered solutions,” but the focus and details differ.

Eric Kimberling, the most recognizable independent ERP and SCM expert in the world, reported valuable McKinsey research figures: “The total value of the omnichannel distribution will continue to grow 7% every year, from $600 billion in 2019 to $840 billion by 2025.”

The focus on the customer will be even more important: businesses will seek more solutions to deliver a seamless customer experience and minimize the costs of canceled orders and returns. Voice commerce, chatbots, and touchless interactions are bright examples of possible solutions for establishing a better customer experience.

PWC, an auditing and consulting company, reports the growth of a sharing economy. They calculated the projected sharing economy market growth to $335 billion by 2025. To benefit from the sharing economy concept companies need to rebuild their business models (e.g., rather than performing the logistics processes independently, they can pair with the third parties).

DHL, following this trend, introduced a “custom share labor” solution that enables warehouse managers to pool shifts between the facilities and gives an opportunity for the workers to deliver their services flexibly from multiple locations where companies need them most.

Intelligent workflow integrates analytics, AI, and ML as well as processes automation. SAP, an ERP software developer, draws the attention of business owners that intelligent workflow drives real-time data analyses and produces a lot of smart insights giving the possibility for the stakeholders to relocate staff and machines to better places in the system for more efficiency.

The main trend of 2022 is dealing with data smartly and in such a way that the company not only meets the demand but is able to generate an understanding of which product is needed at which time. Intelligent workflow contributes to this understanding much via:

- agile operating models;

- dynamic computing;

- self-learning operations; and

- customizing customer experience.

To recap, the 2022 SCM trends overview is all around the “closer to customers, closer to technologies” concept. DHL, in its “Logistics Trend Radar,” paper emphasized that in 2022, the supply chain will undergo “tremendous innovation” in spite of the fact logistics industry has never been the first one to implement new technologies.

Tips to streamline your supply chain processes

From the beginning of this year, DHL works directly with 100 startups in the field of logistics and tracked more than 1000 ones. They want to bring more value to those, who are willing to transform the supply chain management processes and improve their business performance. Hence, it’s possible via streamlining supply chain processes and the introduction of new SCM solutions.

Forbes reported that supply chain streamlining solutions will even get the boost from the governments. They have begun testing blockchain for smoother and more accurate paper workflow inside the supply networks. AI and blockchain will push the “immutable record” of the events throughout the supply chain and utilize data for better performance.

Dealing with supply chain data for better performance

CIPS, serving procurement and supply research, says “integrating supply chain data and eliminating the duplicated one” is resulting in labor time optimization and error number decrease leading to lower costs.

Any supply chain transaction normally touches several system layers: ERP system, sales, and procurement forecasts, and manufacturing planning. In small and medium businesses data sharing is possible via uploaded sheets or shared documents, but in the case of business growth and scaling it demands software solutions.

Big data is part and parcel of every supply chain component. Companies integrate big data analytics in their everyday process for more improvements. Thus, for example, Blue Yonder has developed data-intensive forecasting methods. They deployed big data analytics to generate 150 million distributions every day with 130 000 SKUs and 200 influencing variables. It sounds powerful to be aware of big data’s importance.

Due to big data processing on a transactional basis, supply processes can be sensed in real-time to identify deviations from a normal pattern and react quickly. Big data-powered solutions give an opportunity for the companies to implement “Google-trend”-style information and social data to predict supply chain disruptions.

Big data is a real path to “should cost” understanding in costs forecasting and financial planning.

Using AI for SC streamlining

McKinsey reports AI-powered solutions as a “tremendously boosting tool” for operational sustainability increase, implementing demand sensing for short-term changes, integrating supply chain and manufacturing, and, as a result, keeping business more resilient.

AI solutions establish end-to-end supply chain transparency and generate faster decision-making. Because, in procurement, you have full data integration with the suppliers, optimization in raw materials, and spare parts purchasing schedule based on precise price forecasting.

AI technology enables planning and execution through the digital control tower and is helpful in the risk-adjusted margin setting. Echo transportation company utilized AI-powered solutions to enable rate negotiation options on the website, freight tracking, and recording clients’ preferences while delivery arrangement.

AI assists Havi in offering solutions for warehousing and freight management based on predictive analytics. They use machine learning to prioritize equipment maintenance and maximize uptime as well.

Symbiotic designs and tests AI-powered robots to optimize operational flow inside warehouses and storage premises.

McKinsey outlines the priority function of a supply chain as a “central cross-functional brain” inside huge corporations. And they considered the fact that mostly in 2022 companies were starting to concentrate not only on the high performance of the local SC functions but on company global value increase due to integrated supply chain management improvements.

Supply chain risk management solutions

Hitachi outlines basic supply chain risk management strategies, considering which they stress the thought that “risk mitigation can be hard due to globalization and cyber interference.” They say prevention and preparedness are the key success factors rather than dealing with the fault directly afterward. Hence, it’s better to apply risk management solutions giving the possibility to forecast and prevent risks.

To increase your supply chain resiliency, risk management tools should focus on:

- Multisource: categorizing suppliers not only measuring how much you are spending but also by potential impact in case of their disruption

- Stress test often: learn and predict what will happen in case of vulnerabilities occur

- Building buffers for inventory and capacity (e.g., consider products stocking additional preventive measures during hurricane season)

ID Agent, a provider of innovative digital risks protection solutions, drew attention to the necessity of prevention rather than tackling the occurred problem. They say supply chain attacks have increased by 78% in 2021. Malicious hacking attacks take place every 39 seconds. And that fact prompts every business owner to consider how to protect the supply chain utilizing innovative supply chain management solutions.

How to integrate SC solutions from A to Z for better revenue

Management of the supply chain touches every supply chain layer (sourcing, planning, procurement, storing, delivering). It doesn’t matter whether you apply out-of-the-box or custom SCM solutions to synchronize your physical, financial, and information flows. They will bring you the following benefits:

- Costs reduction

- Labor resource optimization

- Better customer experience performed

- Longer equipment uptime due to more precise monitoring and risk management systems

- Deeper business insights due to AI and Big data-driven solutions

To integrate supply chain management solutions, map all the business operational processes, remember about existing vulnerabilities, and predict the impact of possible supply chain disruptions.

In this blog, you read about SCM 2022 trends: from customer focus to omnichannel communications high performance, and about AI technologies’ continuous boost to blockchain tech utilization for more security. But the main message of 2022 in supply chain management is not only to meet the demand successfully but be able to generate the demand due to smart processing of big data and predictive analytics deployment.