Three Main Uses for IoT Solutions in Cold Chain Management

Smart cold chain management has never been more vital. High demand for refrigerated system capacities is spurred by the increased need for higher-quality fresh produce, preferably organic. Statista claims the global food and beverages market will grow by 10.3% annually, resulting in $153 million in revenue by 2023.

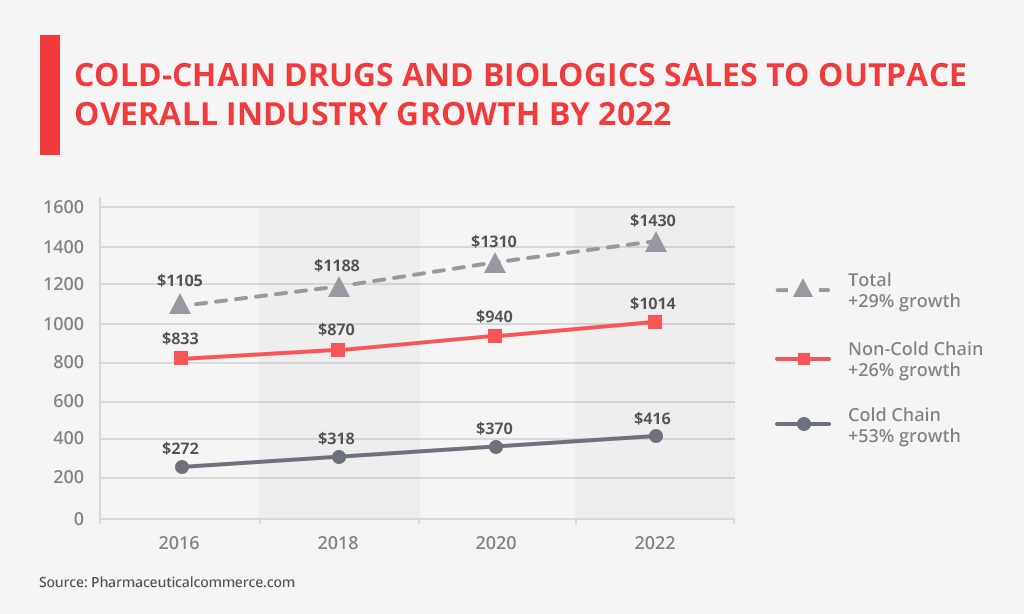

The pharmaceutical industry is also growing more reliant on cold storage facilities. The Pharmaceutical Commerce’s recent findings foresee a 12.7% yearly increase in cold-chain drugs, putting another strain on cold chain logistics.

The situation is aggravated by the strict regulations governing the storage and shipping of perishables. For cold chain logistics, there are too many participants being held accountable for stocking, packaging, and hauling. Each minor mistake, be it improper temperature control, light, vibration or humidity, may lead to extra costs and spoilage. It may take just a few days for some light- or temperature-sensitive drugs to lose their efficacy and become harmful for patients, risking the reputation of pharma companies.

Cargosense.com confirms that 20% of drugs are wrecked because of cold chain malfunction. Food waste is even worse. BCG states that 1.6 billion tons of food are damaged or wasted every year and this figure is expected to increase annually by 1.9% from 2018 to 2030.

However, this loss can be eliminated. BCG’s investigation has revealed five major change drivers that will help to reduce food loss.

The same holds true for other cold chain goods. One major challenge is establishing end-to-end visibility so that all cold supply chain silos can operate as one. Therefore, the adoption of emerging technologies, like the Internet of Things (IoT), becomes a prime focus. IoT-enabled loggers stay connected 24/7 and allow for timely problem-solving.

Driven by expectations to streamline cold chain operations, logistics, and transportation, businesses are likely to invest over $40 billion in IoT solutions by 2020. Let’s dig deeper into the matter and investigate their main uses.

Resolving Cold Storage Issues on the Go

Unlike dry storage, cold storage operators have more to maintain. Warehouse refrigeration systems and frozen distribution centers supplied with chillers and freezers are the biggest energy consumers and require following strict design and construction requirements.

They must operate 24-hours-a-day while sustaining the appropriate temperature levels for a wide range of commodities. According to Supplychaindive.com, cold storage facilities consume about $30 billion in power per day. This is why the supply chain industry and cold chain, in particular, is second on the list of IoT investors.

Cold chain operators must also manage post-construction challenges, such as maintaining energy efficiency, temperature balance, and seamless chain operation.

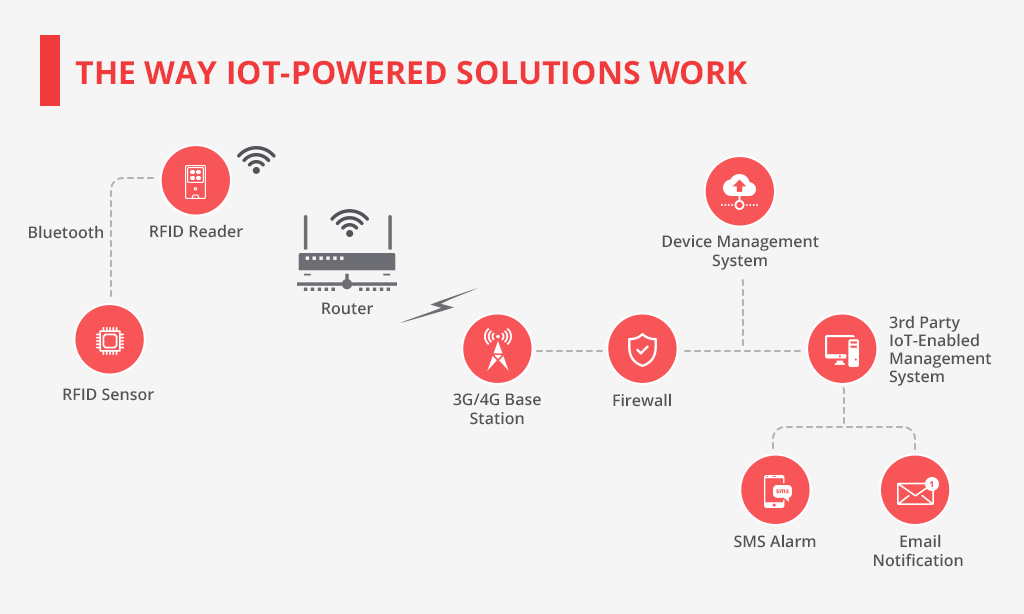

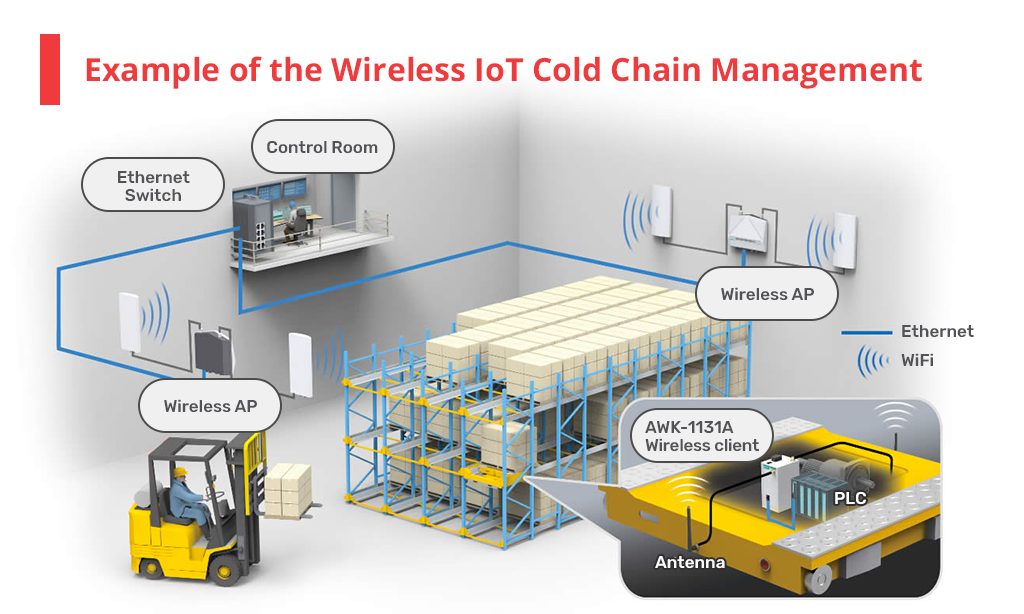

To avoid breakdowns, cold storage providers deploy IoT-enabled monitoring solutions like embedded sensors. Installed throughout a cold chain facility, freezers, chillers or containers, these sensors collect data on environmental conditions and promptly send failure alerts via 3G/4G or LAN networks. They transmit the aggregated data to warehouse management systems fostering a coherent tracking network.

There is no doubt that incorporating IoT-based solutions requires ongoing cold chain transformations. They must transition from outdated cooling containers to other shipping packages to ensure better temperature control, real-time data monitoring, automated reporting, and predictive analytics. In simple terms, IoT-enabled chains have the following sequence of action:

When implemented correctly, cold chain logistics has fewer constraints on its way. Maersk is one of the early adopters having put IoT to use. A Danish shipping leader has built a Remote Container Management (RCM) suite, which is to help shippers track temperature in refrigerated containers.

Fresh Produce Journal says RCM spotted 4,500 temperature irregularities within first six months of its trial use. 200 errors detected could have caused big damage to commodities. The tool does not only give control over refrigerated cargo shipments but it also enables Maersk to further increase its cold chain market share.

Bringing Automation to Cold Chain Operations Management

Apart from real-time asset tracking, the data obtained through the IoT-powered sensors allows stakeholders to better understand the risks involved, improve operational output and distribution schedules. This inevitably translates into high customer retention, as cold chain logistics becomes more streamlined and visible.

When IoT-based solutions come into play, there is no need to check temps or environmental conditions of cold storage manually. What is more, even goods freshness can be verified without human assistance.

A Florida-based startup Freshurety places IoT sensors inside food palettes to continuously record the ambient temperature and examine the fruit and veggies gases and predict when expiry dates arrive. Being used by Driscoll’s berries and AmazonFresh, this technology allows for more efficient stock management, since ripe palettes will be timely spotted and utilized, preventing unwanted food waste from taking place.

Accurate inventory control is another benefit received with IoT hardware. Wireless automated inventory tracking is less error-prone than standard methods. Earlier, each stock item required manual scanning with a device at checkpoints. If failed, the data acquired by cold storage operators could be inconsistent, resulting in audit deviations, spoilt commodities or huge penalties imposed. IoT technology makes a difference, eliminating the risk of shipping delays.

Managing Cold Supply Chain Remotely

Previously, cold storage managers had to be physically present inside a cold storage facility to inspect deliverables and ensure their frictionless work. Considering wide cold chain geography with scattered warehouses or distribution centers, it used to put a lot of constraints around efficient supply chain management.

It also led to miscommunication between stakeholders, as there was no chance for cold chain transparency to increase. No insights into inventory levels, storage capacities, or regulatory compliance.

With the advent of IoT smart sensors and cloud-based software aggregating the data received, cold chain partners can stay in the know regardless of their remote locations. Shipments, storage, and even last-mile deliveries can now be monitored via mobile applications.

This connectivity enables cold supply chains to better handle hand-off points too. For refrigerated cargo shipment, hand-offs often take place during containers movement to or from ports by trucks or rail, when unloading packages, storing commodities in warehouses, etc. The point is, most of the processes are still hand-operated, which often leads to shortened shelf list and cargo loss.

By incorporating remote management systems, hand-off errors become easier to foretell and track. Cargo spoilage is minimized thanks to IoT hardware built-in containers, whereas vehicle routes get optimized with IoT loggers.

Bonus Tips for Successful IoT Solutions Implementation

Eventually, for IoT solutions to release untapped potential, cold supply chains need to grasp the convergence of the IoT use cases, e.g. container tracking may assist in both cargo and fleet management.

Cold chains can draw maximum benefit from IoT provided that an intelligent asset network is created. To achieve the goal, here are some key factors suggested by DHL you may find of the help:

- Establishing a set of unified and clear policies for asset identifiers to be applied throughout the cold chain

- Creating an environment for seamless data exchange between sensors

- Prescribing data ownership roles and drafting privacy policies that address major security risks

At Innovecs, we keep growing engineering expertise in IoT-based solutions as well as warehouse management systems tailored for specific cold chain needs.