Cold Chain Management: How To Preserve Product Quality For Better Revenues

Grandviewresearch.com shares the evaluation of the global cold chain market size as $210.49 billion in 2020 and its forecasted 14.8 % CAGR as of 2028.

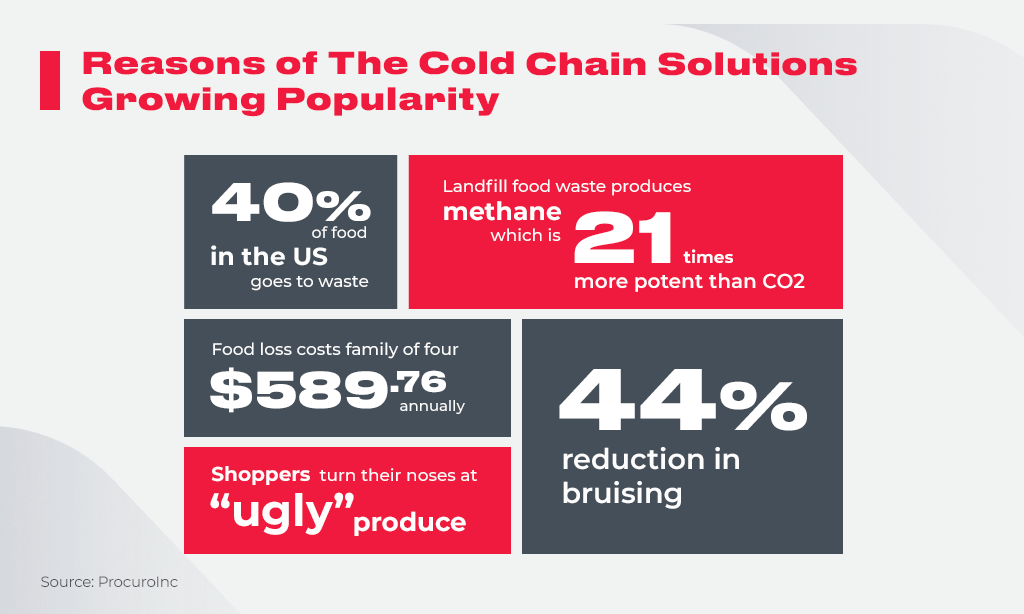

Cold supply chain solutions are getting more and more popular due to a number of reasons, some of which are depicted by Procuro (provider of cold chain management solutions for Food, Pharma, and Chemical Industries):

Added-value of “from farm to fork” food business concept or of fast and in time vaccine deliveries under pandemic situations contribute to your business growth and profits boost greatly. That is why here in our blog we decided to highlight the issue of effective cold supply chain management and solutions bringing growth possibilities to the business.

Cold Chain Logistics And Technology: Their Value For Business

Riskpulse, a supply chain risk analytics company, defines cold chain transportation as moving temperature-sensitive goods (beverages, food, pharmaceuticals) to the end-user in accordance with the standards of special temperature range, storing in the correct packages, delivering via precisely planned transportation routes in the frame of perfect timing. All the sophisticated business processes involved in cold chain management can only be executed smoothly due to the data-driven insights and complicated tech solutions.

Technologically powered cold chain logistics can generate value in many aspects. The two most important are:

- Outstanding added value for the globally important social issues of food wastage, product shelf-life expanding, and medications in-time delivery.

- Great operational value for business processes: RFID supply chain technology, cold chain route management solutions. Cold chain management applications smoothen product delivery to the end-user preserving quality and keeping everything in compliance with the standards.

Both aspects have great potential to generate additional profits, fasten ROI, and improve business scalability. That is why the growth of the cold chain market size period is a high time to implement new tech solutions, develop custom cold supply chain management tools and address logistics challenges.

Cold Chain Logistics Challenges

Inbound Logistics emphasizes in their article on top cold chain management trends that the number of challenges is increasing constantly due to the global market growth and regulations becoming more and more specific. They draw the business owners attention to the following challenges worth addressing via new techniques:

- sensitivity and quality international standards become more sophisticated;

- the necessity to decrease costs because more possibilities for business development are hidden in long-distance deliveries;

- constant “capacity and resource constraints” throughout global trade;

- raise in consumers self-consciousness and knowledge about their bodies and health: they are getting more demanding to the products used every day as well as about medicines quality;

- threat to deliver compromised medication for the patient with probable health damages (in a case when temperature deviations are not strictly declared, but they happen during transportation and are potentially harmful);

- smart understanding of local rules, customs, environmental conditions, and route length estimation.

All the above-mentioned issues can be considered successful while utilizing modern supply chain solutions.

How Technology Deals With These Cold Chain Logistics Challenges

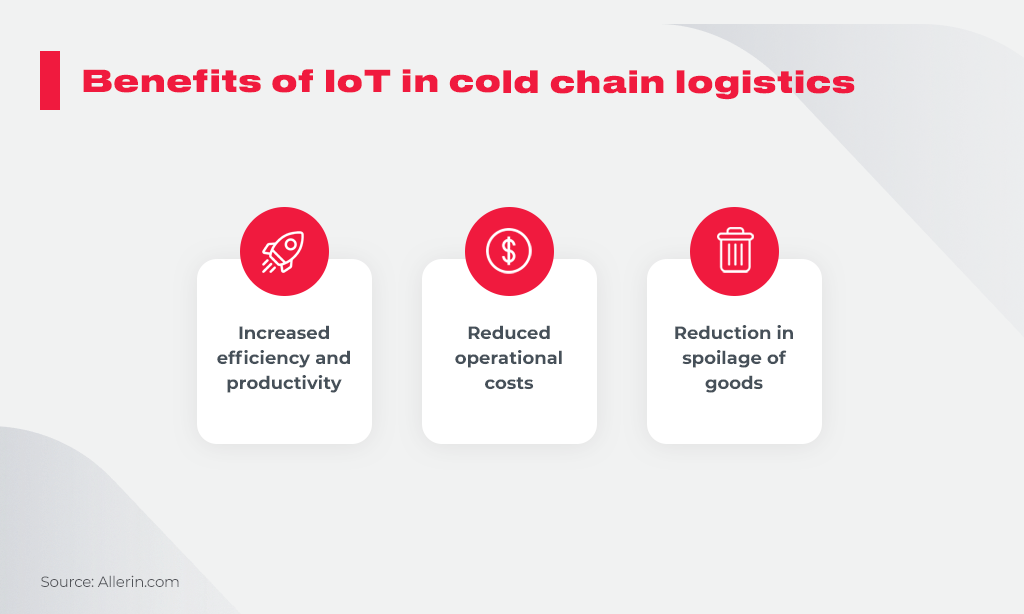

Once the cold chain is about preserving the quality of perishable goods, such technologies as IoT, AI and ML are helpful to manage cold supply chain logistics data and make use of it to adjust logistics operations for better cost-saving, wastes reduction, and bringing more satisfaction to the client.

It’s worth mentioning every technology makes a unique contribution to the cold chain business growth:

- IoT improves temperature monitoring, real-time data access, automated reports generation, shipment tracking. The strong challenge of applying IoT is device installation and maintenance as well as establishing robust Bluetooth, Internet or LAN connections;

- Controlant educational blog outlines that ML and AI perform planning, diagnosis, and robot control in the supply chain. They rely on smart data generation transmitting passive information into active critical business data contributing to in-time analyses (e.g. sensors to produce alerts in case of temperature level breaches).

MHL news portal calculated that average businesses spend 55 hours a week on producing paper document flow, 39 hours for chasing invoices inconsistencies in logistics, and 23 hours to respond to supplier inquiries. It turns out into 6500 hours a year to operate business processes manually. Moreover, they spend the budget to administrate staff performing these tasks. Obviously, automated cold chain management solutions are worth implementing to boost revenues.

Cold Chain Solutions And Their Contribution To Business Revenue Boost

Maersk, an international container terminal operating company, describes cold chain solutions as a set of services export or import oriented as well as end-to-end ones. All of them are tailored to perform high-quality delivery via:

- value protection from logistics-related risks with the help of smart tracking, for example;

- blockchain empowered platforms where single-source secure shipping data is provided;

- VGM (verified gross weight) relevant estimation to calculate real cold chain delivery costs;

- smart contracts among the shipment process participants.

The described solutions deal with a number of cold chain logistics issues such as digitized documentation interchange, disrupted climate control or temperature, delivery bookings, relevant packaging, and its monitoring throughout shipment, transport delays management, product quality auditing. As whole cold chain solutions are aimed at handling all business cold chain needs to optimize supply chain expenditures and increase revenue.

Forbes mentioned in its post-pandemic cold supply chain market research the following quoting Indian Transport & Logistics News:

“Trendy technologies such as AI and ML have become crucial for transforming pharma cold supply chain as well as the other fields as they are able to provide unparalleled visibility and insights of efficiency across all the transportation channels. And in future cold chain management innovations should gain even more global priority”

Successful companies are striving for more and more tech possibilities to strengthen their positions in the global market. Dnata, a leading pharma air service provider, improved its cold chain capacities via special digitally controlled temperature-sensitive containers. FedEx designed a special Cold Chain Center committed to vaccine transportation. PCI Pharma introduced a digital platform enabled by AI to support the clients with real-time insights into their clinical supply chains. These solutions cover all the cold supply chain stages to boost business efficiency and revenue.

Let’s follow deeper insights into successful cold chain management solutions with the representative valid industry cases.

Successful Cold Chain Management Solutions

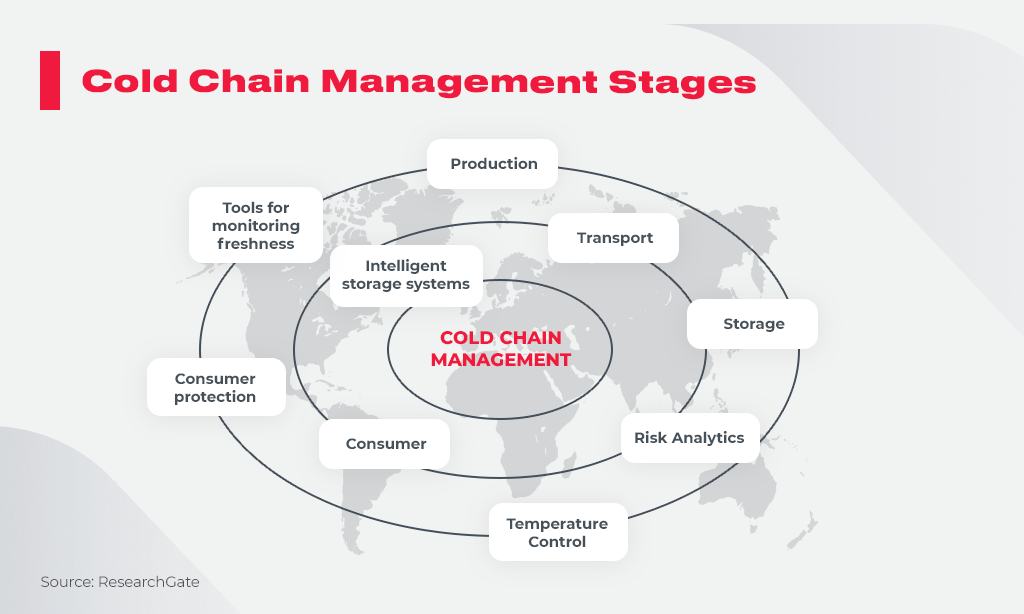

Cold chain logistics solutions are able to monitor temperature at every step of the cold chain logistics process in case your products need to be cooled, frozen or deep-frozen while transportation.

Logmore, a QR tags developer and cloud service provider, specifies that cold chain aspects should be considered by all the participants of the process (manufactures, retailers, and even, end-users). Every solution is tailored to address:

- routine storage and handling processes;

- equipment auditing (storage units temperature, containers sensors);

- emergency procedures for maintaining the delivery (e.g. vaccine inventories);

- guidelines considerations issued by different local authorities (thus, for example, the World Health Organization and the EU Commission have strict requirements for storing and shipping pharmaceutical goods).

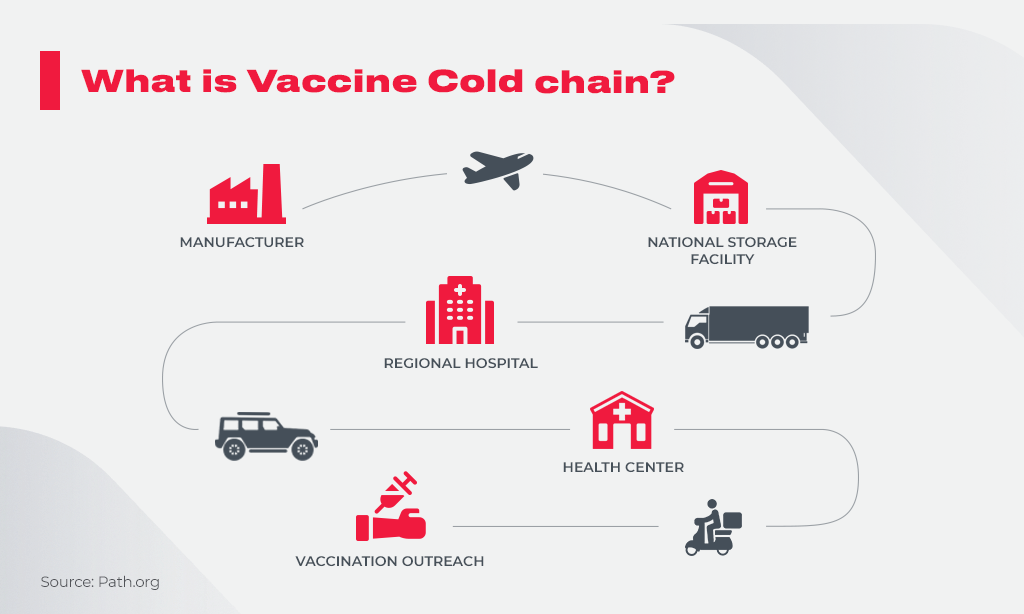

VBI notifies reasonably that cold chain is a “shared responsibility” from the time the product is manufactured till the time it’s administered. It’s especially challenging concerning vaccines. Providers often face the necessity to verify any lapses in the whole chain and make sure the vaccine is truly viable before usage. ACIP (The Advisory Committee on Immunization Practices) recommends not to count vaccine doses mishandled at any stage of the cold chain. That is the reason every custom solution should have proper mechanisms to identify temperature breaches, handle this data and provide it in real time for the decision-makers.

Innovecs Case For The US Cold Warehousing Provider

Innovecs as a provider of tech solutions across the globe has delivered fruitful partnership to the US Cold Storage provider operating 38 temperature-controlled warehouses in 13 states. The main outcome of this collaboration was to totally rebuild WMS performing 8 times faster than before. Joshua Holi, EWM implementation manager at US Cold, noted that rebuilt cold chain management system had become:

- user-friendly and intuitive;

- easily scalable on each location;

- operating faster;

- more visible via trendy, good-looking screen view.

We can tell these are the most important demands of every client to a custom cold chain management solution. Especially in case the client works globally and is willing to have fast access to any location data.

DHL Logistics Of Things

DHL in its blog illustrates cold chain solutions with a great appetite emphasizing their tools empower “the ability to bring fresh Atlantic salmon to the plates of hungry diners in Seoul”. And that is a key metaphor message of practically every cold chain client’s desire: to deliver quickly, to guarantee product freshness and long shelf-life after delivery, and to be compliant with the local regulations.

In their Cold Chain Whitepaper DHL outlines the essentials every company gets implementing their cold chain solutions:

- keeping products at the right temperature due to cost-effective cloud-based GPS-enabled sensors working everywhere (ocean, highway, or rails);

- blockchain-enabled platforms to make the cargo visible at any delivery stage.

These are the true basics empowered by IoT: sensors collect data and transmit failure alerts throughout the supply chain immediately. In such a way it’s easy to keep the cargo fresh like in the next example about avocado deliveries.

“Avocado” TEDx Case

Bart van Riessen performed a bright “avocado logistics case” at the TEDx platform to raise the issues of cold chain management. He described how his company did its best to deliver fresh avocados using electric vehicles. But the issue of this part of the supply chain is that electric vehicles need to be charged often. Talking about this example he revealed the very sense of cold chain logistics: a company has to make every supply chain part work in a simultaneously automated and digitized way to “bring fresh avocados to your shelves”.

This TED talk illustrates how much cold chain logistics is striving for sustainable transformation, and that data processing is extremely critical at every stage (either it is electro bikes fleet management or product quality management).

It’s a vivid example of temperature-sensitive goods shipments. Avocados are subjected to a 9-hour break in cold storage under 1C, and a 24-hour gap in temperature level for changing transport. After shipping, there are certain criteria to assess: respiration, ethylene evolution, fruit hardness, and mass. Breaking cold chain at any stage and no data about the breach resulted in fruit quality decrease, that is the very moment cold chain solution comes in handy. Because you can only imagine how much it costs for the company if more than a day temperature failure is not monitored and fixed.

ResearchGate shares the statistics:

“Storage at 5.5°C resulted in only having between 8% and 30% sound fruit while storing fruit at 1°C resulted in an increase in the percentage of sound fruit to 80% for the control. Breaking the cold chain anywhere in the shipping process reduced fruit quality. This is mitigated by storing fruit at 1°C, but it is imperative to maintain the cold chain from the packhouse to the shipment’s final destination.”

And Hellenic Shipping News illustrates the above-mentioned process.

Ethiopia, Djibouti, and Netherlands governments started a collaboration to deliver avocados from Ethiopia to Europe through the Djibouti port. It is a case of designing a cold chain starting with the first 24 tonnes reefer container. The main challenges they faced were spoilage, long temperature monitoring time, and high dues. Dutch side contributes its expertise in cold chain logistics solutions: they invested several tens of millions of Euros to develop cold terminals under IoT technologies in the port of Djibouti.

These facts ensure the necessity both on the state level and company one to implement cold chain solutions for better business performance.

Overall Spotlight On How Cold Chain Management Solutions Empower Your Business

To recap, efficient cold supply chain management opens new possibilities to any business involved in temperature-sensitive product deliveries. Due to AI and ML technologies, it’s getting easier to manage every operational process from WMS tuning to cold container yard management, from digitized document flow to fleet tracking.

Benefits of the custom cold chain solutions are obvious under:

- growing global demand for vaccines under pandemic situation;

- an expanded variety of customers’ needs and tastes: as they become more sophisticated, it’s necessary to deliver faster and take care of product quality more precisely;

- more complicated local state regulations concerning sanitary norms and health benchmarks.

Today cold chains gather significant data to apply it for business processes optimization. Controlant as a wireless temperature monitoring solutions provider stresses cold supply chain management trends shifted to more focus on transparency and sustainability in procurement, faults monitoring, risks reduction, overall cold chain performance. We can define the main benefits of implementing cold chain solutions such as:

- customer experience improvements: obtaining real valid data contributes lead to response time reduction;

- partner selection improvements using digital platforms to search for reliable participants of the cold supply chain to collaborate with;

- revenue boost due to in-time lapses identification and cost reduction concerning mishandled products.

Seeking innovation has already become imperative if a business wants to grow. Once you decide to develop a custom cold chain management solution, your business has all chances to stay ahead of the competition because you serve the customer smoother, in compliance with temperature restrictions and local regulations, and with better rates due to cost-effective operations arrangements. Innovecs is ready to contribute to all these initiatives!