Digital Supply Chain Twins for 3D Visibility and Cost Optimization

Since the early 1970s, 3D modeling (CAD: Computer-Aided Design) and simulations software allowed companies to create realistic and scalable images of networks to track productivity and provide diagnostics. Due to data mining techniques and IoT sensors, businesses are able to create digital twins of the real objects to feed the model with accurate data and understand what’s happening inside. Over the course of time, digital twins appeared as AI-powered simulations enabling the visualization model to help predict network functionality problems and potential disruptions.

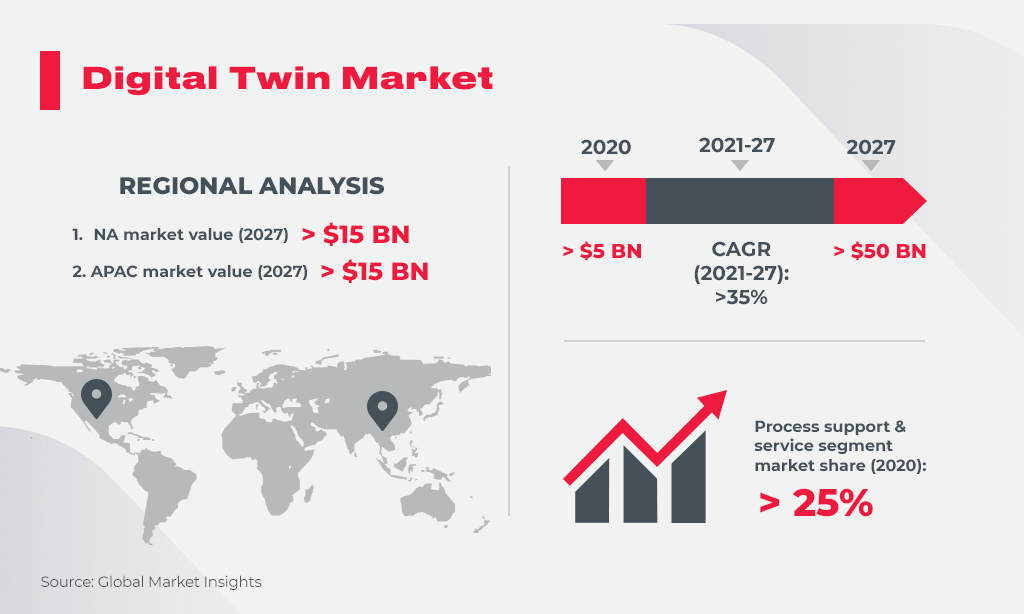

Nowadays, according to Gartner’s research on IoT implementation, 13% of companies working on IoT projects already have digital twins, and 62% are working on their implementation. In its paper about digital supply chain twins in logistics, DHL emphasized the expected growth of the digital twins market “at an annual rate of about 38% over the next few years passing the $26 billion point by 2025.”

As a digital transformation tech company Innovecs follows the latest technology trends. And Digital Supply Chain Twins (DSCT), IoT, AI, and RPA solutions are no exception. In November 2021, our company hosted a webinar “Rock Your Supply Chain with Real-Time Visibility” to track the unique features of logistics ecosystems. The preface was to dive into digital twin possibilities in establishing efficient supply chain networks.

We treat the topic of digital twin solutions as a crucial part of enhanced supply chain visibility. For this reason, the blog we published provides a substantial understanding of the digital twin phenomenon and its contribution to an overall supply network in the form of:

- Increased supply chain network agility

- Immediate ROI

- Costs optimization

- Improved levels of customer service

To prepare for a digital twin integration for your company let’s examine this paper for a deeper awareness of the technology and its influence on business operations.

Understanding Digital Twins

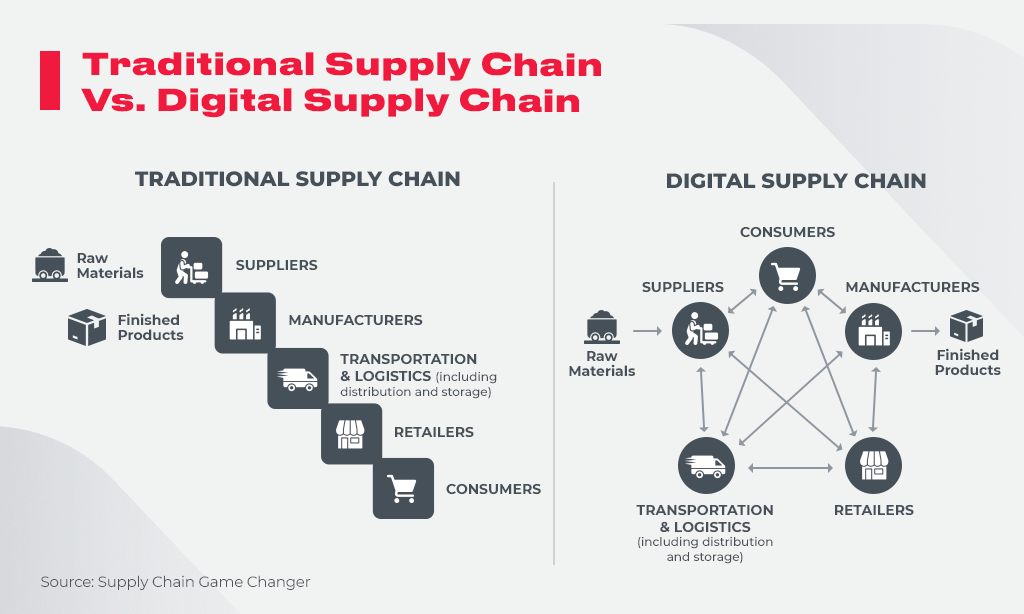

Ernst & Young, a British consulting company, stated in its video review that supply chain digital twins are a “detailed simulation supply chain model” contributing to the supply chain’s decisive move from reactive to perspective and predictive functioning. They outlined the core vision of a digital twin as a tool for increasing supply chain resiliency in the face of uncertainty and disruptions.

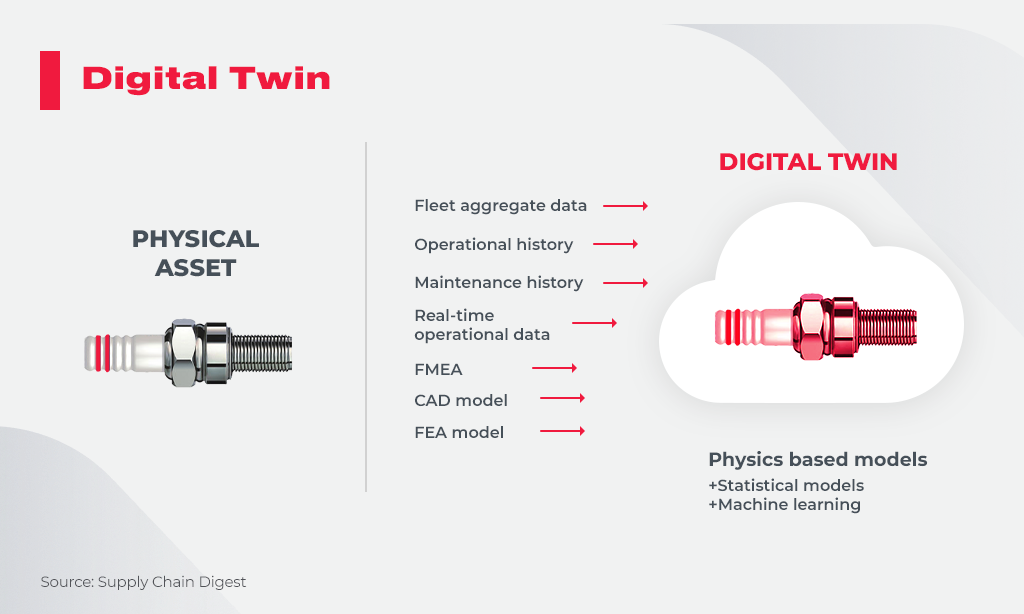

Digital twin technology opens new possibilities of prescriptive supply chain network functionality due to the ability to react to unforeseen scenarios which can lead to supply chain bottlenecks and inventory imbalances. A digital twin of a physical supply chain asset deals with sourcing, manufacturing, and transportation issues: stockouts, machine disruptions, traffic congestions, and warehousing vulnerabilities.

IBM identifies a digital twin as a:

- Virtual replica of a real object

- Tool to “understand the present and predict the future”

- Set of software operating system characteristics visualized

- Solution for faraway asset troubleshooting

- Way to manage the complexities and linkages within a system-of-a-system

Google launched a “digital tool for logistics,” a Google cloud solution enabling a virtual representation of an existing supply chain. They stressed the following use cases of the tool alongside the Supply Chain Pulse Module (dashboards, analytics, collaborations in Google workspace): organizing data for a “completely sufficient view of the suppliers” and preventing stockouts. In 2020, the estimated cost of all out-of-stock items was $1.14 trillion!

To tackle the above-mentioned supply chain issues, stakeholders can use either ready-made solutions or develop custom models to bring together data from multiple sources on a virtual platform for agile decision-making. Subsequently, digital twin technology lets companies increase scheduling agility and reduce operational costs. Ernst & Young estimates an increase of 5-10% in supply chain throughput and stresses the monetary benefits reflected in higher ROIs and revenues. In reality, the technology is worth paying attention to if stakeholders are willing to make the investment in true digital transformation.

Digital Twin Technologies

DHL outlines several technologies enabling a digital twin creation and utilization:

- IoT: The Internet of Things enables the collection of data from a variety of objects and a digital twin is an ideal way to structure, access, and analyze complex supply-chain related information

- Cloud computing: managing digital twins requires processing power and storage capacity, and the affordable pricing model of SaaS delivers bigger possibilities to implement digital twins even for small and medium companies

- APIs and open standards: companies apply software development to design friendly interfaces for interactions with a digital twin

- AI is used for extracting valuable insights from the complex data depicted by supply chain digital twins

- Augmented and Virtual Reality let companies interact with a digital twin, depict it on a screen, or present it as 3D models for better processes, vision, and understanding.

Matthias Heutger, Global Head of Innovation & Commercial Development at DHL, specified in one of the corporate press releases that “digital twin technology offers unparalleled capabilities to track, monitor, and diagnose supply chain assets and facilitates data-driven decision making.”

Digital twin technology creates descriptive values (enabling immediate visualization of remote or dangerous objects); analytical and diagnostic values as well as predictive ones. Adopters of digital supply chain twin solutions admit benefits in four areas: collaboration inside their company, business processes streamlining, new business model creations, and adoption. At the same time, they may face some essential challenges of a digital twin implementation.

Challenges of a Digital Supply Chain Twin Implementation

While leveraging digital twin adoption we came across the following stumbling blocks:

- Cost and budgeting for digital twin projects

- Precise representation of the processes

- Data quality

- Cybersecurity

- IP protection

- Interoperability: in spite of common standards some technical data is complicated and hard to transmit between supply networks. Sometimes it’s difficult to replicate the functionality of AI-powered solutions provided by a single vendor.

Considering the enumerated challenges, it’s worth stressing that the rapid pace of technological change is still the biggest challenge. And once you decided to transform your supply chain via digital twins, you need to be ready for deep collaboration at every level of your company, encouraging staff to experience continuous prompts, errors, and adjustments to perform a substantial digital change.

Janina Kugel, Board Member and Chief HR Officer at Siemens explained in her study on happiness and productivity that during digital twin launches and other high tech solutions, “managers should be ready to communicate openly across all company levels,” to collaborate with all parties of the supply chain structural departments. And only a deep overall organizational change will work to facilitate digital twin technology and a successful implementation strategy.

Use Cases of Digital Twin Solutions

The objectives of a digital twin utilization plan may vary across companies depending on their supply chain’s unique features. GE presents new clients with software and technology allowing companies to build digital twins of their machinery for tracking its performance. Microsoft delivers Azure Digital Twins and Project Bonsai modeling relationships and interactions between people throughout the supply chain. Hans Thalbauer, Managing Director of Supply Chain and Logistics at Google Clouds, specifies that supply chain twins are not only a process-enabler for your company, but it’s a perfect tool for customers “to obtain deeper insights into operations”.

All these examples are about the cost-sensitive nature of supply chain components: sourcing and stock, transportation, and customer behaviors that influence your tech investment. In addition, digital twin solutions have the primary objective of addressing supply chain bottlenecks to provide smooth logistics operations.

Over the course of time, technology improvements will cost less, confidence will grow, and stakeholders will introduce supply chain digital twins through a wider range of use cases:

- Packaging and containerization: companies are doing their best to increase sustainability, and material digital twins are helpful for testing and tracking the performance of new environmentally friendly components of packaging. 3D photographic technologies (German Metrillus startup) create a container model to identify possible cracks or dents and prevent damages

- Digital twins in shipments: modeling freight size and shape to pack containers more efficiently

- Digital twins of warehouses and distribution centers to manage assets including space optimization, simulating product movements, and staff transitions

- Digital twins of logistics infrastructure to reflect the processes of logistics hubs (cargo airports, container ports)

- Modeling of global logistics networks: depicting not just logistics assets, but also oceans, railway lines, and highways for better mapping and understanding of supply chain processes

- Digital twin applications enable deeper collaboration with your suppliers due to shared demand forecasting using shared data. The same data comes in handy for your suppliers, allowing them to use VMI (Vendor-Managed Inventory) for more flexibility.

After reading these use cases on the benefits of digital twin technology and the agility it brings, we hope you will consider early adoption. Companies can react quicker to market fluctuations, apply prescriptive operations, and utilize beneficial planning which leads to a faster and larger ROI in addition to overall costs reductions.

Conclusion: How Digital Supply Chain Twins Make You Twice As Agile

In the future, logistics professionals will expect their digital twins to grow exponentially. From their individual applications to the interconnected ecosystems uniting supply chains from end-to-end for more visibility and more informed decision-making. Supply chain twins as models of existing supply chain assets are valuable tools for your company in terms of logistics network resiliency.

Klaus Dohrman, VP at DHL Customer Solutions and Innovations, stresses digital twins’ value because they “unlock multiple opportunities for the industry, reduce waste, and grant ultimate customer experience driving more revenue for businesses.”

Twins are part and parcel of a digital supply network, where sourcing, manufacturing, and transportation are interconnected, and high-quality data is picked from various sources to assist in supply chain management. Every digital twin use case, whether it is containerization or shipping, warehousing, or establishing your overall logistics infrastructure shows that digitized supply chains, presented as models, provides more possibilities for stakeholders to:

- React properly and in time

- Adjust critical supply chain components

- Reduce operating costs

- Apply insights driven by supply chain data analyses

- Be ready for market fluctuations and company changes beforehand

Many famous digital market leaders (GE, Google, Microsoft, DHL) provide ready-made Digital Supply Chain Twin solutions to mimic a replica of your supply chain. If you feel like you’re missing the boat, it’s time to contact Innovecs to help design and build a customized Digital Supply Chain Twin solution for the future of your company, suppliers, and customers.