Harnessing Digital Supply Chain Transformation for Asset Maintenance

In the wake of the pandemic, companies have encountered a myriad of challenges, including manpower constraints, disruptions in supply chain schedules, and evolving regulations on imports and border crossings. In these trying times, digital transformation emerges as a crucial avenue for companies to remain competitive by enhancing customer service and cost efficiencies. As businesses navigate the dynamic landscape, embracing digitalization becomes a pivotal choice for sustained success.

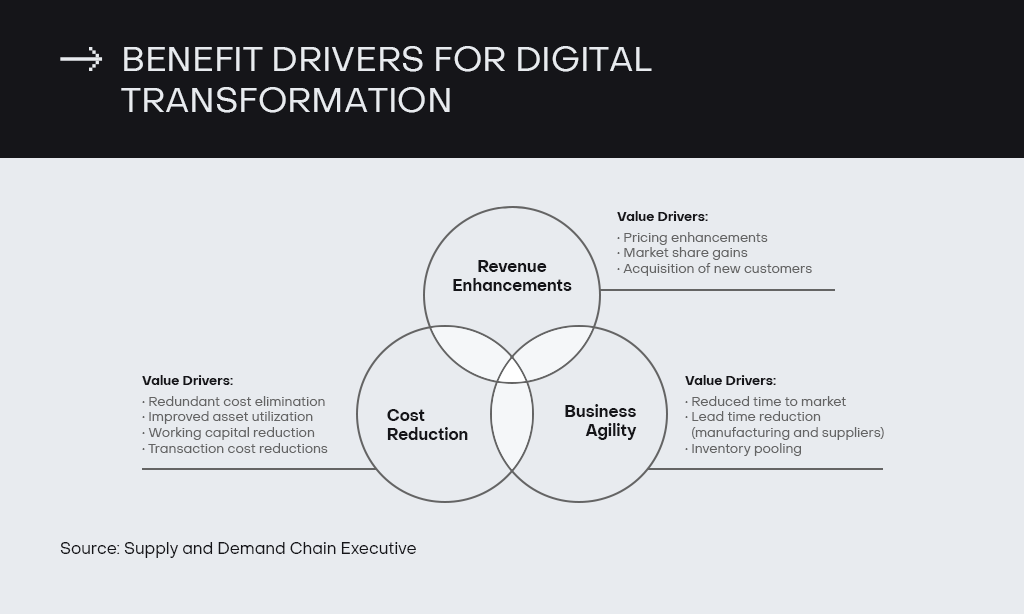

The Council of Supply Chain Management Professionals outlines three key drivers for planning your supply chain digitalization:

- Keeping up with your customer’s evolving demands.

- Urgently automating routine operations to optimize staff productivity.

- The overarching desire to enhance overall business performance.

In this whitepaper, we discuss trendy technologies and their distinctive features that lead to digital transformation success. Additionally, we address the challenges of implementation and explore technology adoption frameworks to guide your journey towards a digitally empowered supply chain.

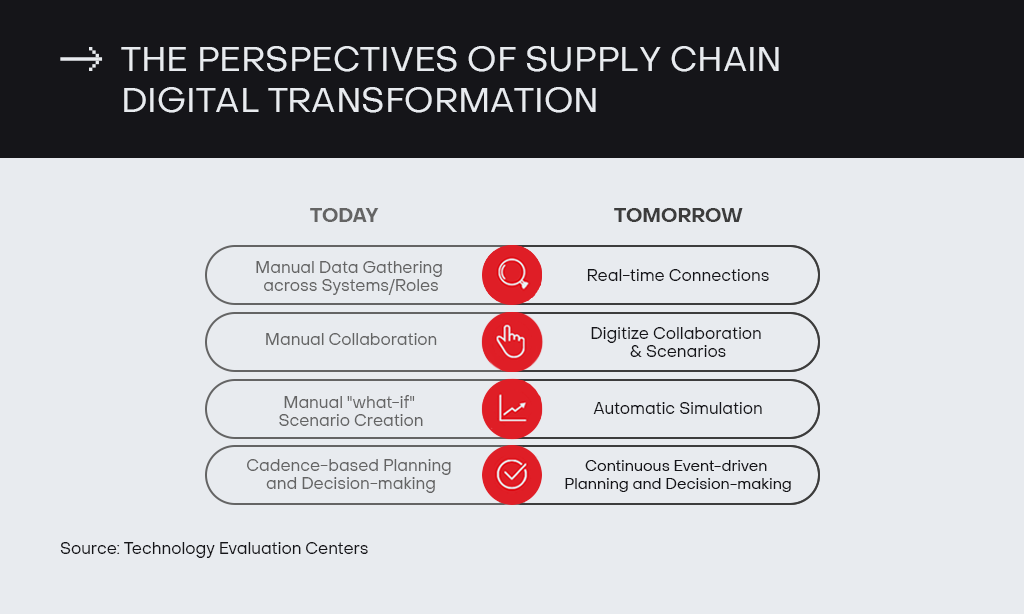

The Perspectives of Supply Chain Digital Transformation

Digital transformation is shaping the supply chain landscape through various avenues, including the advancement of smart logistics with automated warehousing, autonomous trucking, and remote fleet management. It also involves the implementation of demand-driven supply chain management and the establishment of a digital thread, facilitating seamless communication throughout the supply chain.

These technologies bring about significant changes, enabling value co-creation within the supply chain ecosystem. Stakeholders now have the ability to shape customer expectations and generate new value propositions, fostering enhanced collaboration. According to the BDO accounting firm blog, digital transformation is creating a transparent “network of networks,” where data is shared not only among insiders but also with partner organizations, opening up new opportunities for collaboration and growth.

Enhancing Supply Chain Business Performance through Integration

In an interconnected supply chain, each technology plays a crucial role in addressing different challenges. These include complexities in product management, precise planning, and effective budget allocation. To achieve advancements through technology, it is essential to have a clear understanding of your business and potential bottlenecks in shipping.

In their 2023 report, Gartner highlights the latest promising technologies for supply chain management, including actionable AI, smart operations, mobile asset optimization, industry cloud platforms, employee engagement, cyber resilient supply chains, and supply chain integration services. They emphasize the significance of human involvement in business processes, even as advanced high-tech solutions are integrated, recognizing the need for human validation, decision-making, and collaboration in leveraging these technologies for effective supply chain management.

Simon Jacobson, VP Analyst in Gartner’s Supply Chain Practice, identifies three key motivations driving the categorization of this year’s technology trends in supply chain management. These motivations include pioneering new forms of engagement, optimizing for resilience, and scaling performance to enable technology to be accessible “any place and any time.” These motivations highlight the importance of embracing innovative approaches, ensuring adaptability in the face of disruptions, and maximizing the availability and flexibility of technology solutions throughout the supply chain.

According to IDC researchers, by 2026, 55% of G2000 OEMs will redesign service supply chains using AI, resulting in 75% issue resolution before failure. Additionally, warehouse automation is expected to increase tenfold by 2028, leading to a 30% improvement in task productivity. These advancements signify the limitless potential for business value through supply chain innovations.

Supply Chain Digital Transformation Technologies

Digital transformation is a widely discussed topic in many companies. Surprisingly, McKinsey Consulting’s calculations reveal that the average level of digitalization in supply chains stands at just 43%, the lowest among the five examined business initiatives.

When it comes to supply chain improvements through digitalization, it’s not simply a matter of selecting and integrating technology into existing processes. It requires a comprehensive strategic vision for the entire company, ensuring that the technology is effectively integrated within the current structure to avoid unrealistic expectations.

Logistics predominantly utilize technology to streamline transactions, support core operations, and enhance data analysis for informed decision-making. However, as highlighted by McKinsey, there remains a challenge in combining cross-functional data and effectively leveraging advanced analytics for demand forecasting and performance assessment. To overcome these challenges, we recommend closely following the profiles of emerging technology trends to better understand their potential and practical applications.

Robotic Process Automation (RPA) & Hyper-Automation

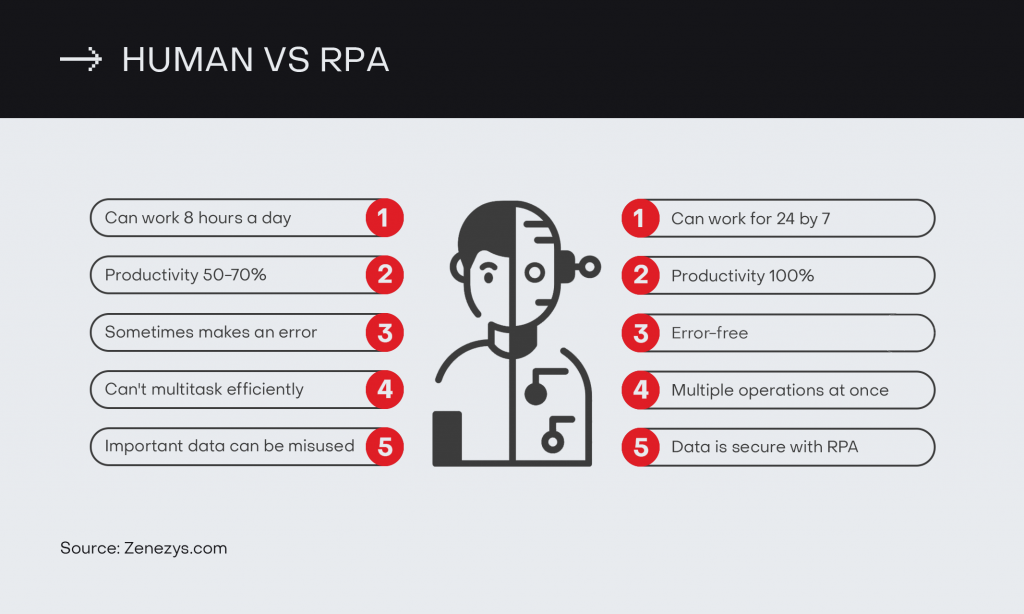

Gartner refers to hyper-automation as a “business-driven approach” used by companies to identify and address the processes necessary to be automated for better KPIs, more revenue, and faster ROI. No digital transformation is possible without RPA and the complete replacement of routine human operations throughout the supply chain networks by robotics alternatives.

According to Polaris Market Research, the RPA market size and share was valued at USD 2.66 billion in 2022. Forrester states “one in every four information workers inside the supply chain networks receives help from software bots,” a fact that proves RPA is capturing the industry.

As a growing technology trend, RPA enables the rise of IPA (Intelligent Process Automation), the gradual elimination of paperwork, RPAaaS mainstream trends, the efficient blending of human experience, manual and digital efforts, as well as the proliferation of RPA across the components of the supply chain.

RPA improves business processes via automation, elimination of human errors, cost reduction for staff administration, securing data, and rocketing robotics multitasking. The Dubai Expo 2021 proves that every country is striving for robotics development and implementing robots in every field including the supply chain.

Digital Twins

For years, scientists have been utilizing mathematical structures to represent real-world objects in 3-D models, enhancing their visualization. Through network technologies like grids and sensors, we can connect assets, reporting, and diagnostic features to the digital realm. As a result, real-time changes observed in physical objects can now be reflected and observed within a digital model. These holistic images derived from the models offer valuable insights for assessing the physical aspects of assets or business processes, enabling better control and management.

In practical terms, digital twins can take various forms with a blend of features. Companies often incorporate familiar technologies like existing 3-D modeling, simulation, and asset-tracking to model business processes, resulting in improved monitoring, tracking, and throughput maintenance. However, digital twins offer much more than meets the eye. Here are the distinctive features that set real digital supply chain twins apart from other digital models:

- They represent virtual models of real “things.”

- These models simulate physical processes.

- Digital twins are authentic and unique, essentially living models.

- They remain connected to their corresponding objects, updating themselves in response to system fluctuations.

- Digital twins provide the value of visual inspection, analyzed content, and predicted context changes.

When leveraging digital twins, several key challenges may arise:

- Cost: Creating and maintaining complex asset models in real-time can strain computing capabilities, resulting in significant budgetary requirements for digital twin implementation. Investments in technology platforms, model development, and ongoing maintenance must be carefully considered.

- Precise Representation: Achieving a perfect representation of reality in digital twins is a formidable task, especially for complex objects with vast amounts of physical, chemical, electrical, and thermal data. Engineers must strike a balance between model simplicity and data quality.

- Data Quality: Accurate data is essential for high-quality models. However, dealing with numerous sensors, diverse working conditions, and volatile networks can complicate data collection. Engineers must develop methods to isolate inaccurate data and address faults in data streams.

In some cases, investing in comprehensive digital twins may not be feasible, leading companies to focus on critical parameters using an IoT system based on sensors and conventional databases, which can save costs.

Due to the cost-sensitive nature of logistics activities, few companies have fully embraced digital twins. Instead, they prioritize creating digital twins for essential components, such as packaging, containers, shipments, warehouses, distribution centers, and global logistics networks. This selective approach allows companies to address specific needs while managing their budget effectively.

Supply Chain Visibility

Digital twins play a crucial role in enhancing supply chain visibility by enabling the tracking of parts, components, and products in transit. This contributes to supply chain strengthening, security, and the availability of critical supply data for all stakeholders.

Supply Chain Visibility (SCV) revolves around effective data management, empowering companies to prevent inventory shortages, delivery delays, and other disruptions. Consider the scenario of tracking spare parts from China to a US plant, where a diverse array of digital tools, such as fleet tracking systems, internal communications, and CRM for customer management, all contribute to supply chain visibility within a broader ERP system.

Investing in supply chain visibility brings several benefits, including the application of suitable software to enhance key performance indicators and address logistical challenges across the network. This, in turn, leads to improved customer satisfaction, compliance with international regulatory requirements through the monitoring of shipping schedules, transactions, and new regulations, and heightened competitiveness by swiftly managing inefficiencies and reducing costs.

To embark on the journey of improving supply chain visibility, starting with the right technology platform and a focus on process improvement is sufficient. Additionally, seeking transparency through API-powered networks will enable greater efficiency and insight into supply chain operations.

API-Powered Networks

An Application Programming Interface (API) plays a vital role in enhancing the openness and optimization of core supply chain functions. The smooth flow of data to end-users has become crucial in modern supply chain management, and APIs serve as connectors between distinct systems. For instance, a Transportation Management System (TMS) might be used for locating carriers and scheduling movements, while an order management solution handles e-commerce transactions, shipping setups, and customer notifications. By building an API, these diverse systems can interface and share essential data seamlessly.

When integrating APIs, a gradual and well-planned approach is recommended. Slow and concise implementation ensures smoother transitions with fewer errors. However, it’s essential to be cautious, as some API developers may suggest a TMS or OMS system solely for financial gains, leading to ongoing training and updates to maintain the systems.

The most common mistake that logistics companies make is that they overestimate their capabilities. For command centers, this usually means using API solutions that are more complex than needed. As a result, you face higher expenses for staff training and potentially more errors.

To avoid this all-too-common problem, following a plan of gradual API integration is typically the best advice. A slow and concise implementation is the best way to ensure a smooth transition and fewer mistakes.

Big Data & IoT in SC Digital Transformation

The autonomous trucking supply chain trend hinges on a fundamental feature: data. However, in March 2020, Starsky Robotics faced challenges and ultimately closed its autonomous vehicle business units. According to Stefan Seltz-Axmacher, the CEO, the main reason behind this closure was not a lack of demand for the trend but rather the significant investment requirements and numerous safety issues involved.

Xeneta, a prominent ocean and air freight rating platform, defines Big Data as a combination of standard transportation costs and scheduled arrival times, along with extended additional information such as changeable data (e.g., GPS alerts or RFID metrics). They recognize the immense significance of big data in freight transportation decision-making. Key applications of freight big data encompass analytics for shipowners, data engineering, vessel performance management, and fleet situational management.

Here are some key areas where big data plays a crucial role:

- Providing the most economical delivery solutions for clients: The availability of comprehensive information variables for carriers and shipowners (e.g., ETA, vessel specifications, market insights, and load size) facilitates the arrangement of optimal freight transportation deals. The use of AIS (automatic identification system) helps consolidate and integrate big data.

- Improving supply chain operations: Leveraging big data processing aids in selecting the best operational modes, including truck speed, fuel consumption, and route planning.

- Obtaining references from various entities (inspectors, terminals, port authorities) to monitor vehicle status throughout the supply chain.

Interesting Fact

TuSimple, a company developing autonomous trucking technology, predicts the appearance of autonomous trucks on roads by 2024. Although currently, it serves as a system for danger avoidance, capable of providing a 360-degree view around the vehicle and monitoring the surroundings up to 1000 meters ahead to prevent hazards. Human-free trucking, a concept involving AI and ML data processing and analysis, aims to enhance safety and business efficiency in the transportation industry.

Adopting a Digital Model

According to observations by Global Trade Magazine, the concept of “elastic logistics” holds significant importance in the realm of supply chain technologies. The dynamic and flexible nature of conducting business in the tech environment allows for the integration of various technologies to meet companies’ scaling initiatives while considering market volatility.

These technologies, discussed in the article, offer valuable assistance in tailoring supply chain solutions, spanning tracking operations, warehouse management, and streamlined product supply to disintermediate shippers.

To achieve successful digital transformation, stakeholders should focus on understanding customer needs, defining a transformational strategy, identifying processes for digitization, and implementing tools for performance management. By formulating a well-aligned digital strategy, following a step-by-step roadmap, and selecting appropriate solutions, businesses can fully reap the benefits of digital models.

All digital transformation trends should be implemented via a precisely designed roadmap comprising:

- Vision of the company digital infrastructure

- Retraining and education of the staff

- Deep cross-organizational communication change

- Shift to the agile manner of operations delivery

5 Steps to Build a Resilient Digital Supply Chain

As you can see, digital transformation is imperative for supply chain success. By embracing technology and implementing a digital supply chain strategy, organizations can unlock new levels of efficiency, agility, and resilience. Here are five crucial steps to guide you on your journey towards building a robust digital supply chain:

- Define Your Digital Vision: Start by envisioning the future state of your supply chain. Identify the key objectives, challenges, and opportunities that digitalization can address. Determine how technology can enhance visibility, collaboration, and decision-making across the entire supply chain ecosystem.

- Embrace Data-Driven Insights: Leverage the power of data analytics to gain actionable insights. Implement robust systems to collect, analyze, and interpret supply chain data in real-time. By harnessing the potential of predictive analytics and machine learning, you can make informed decisions and proactively mitigate risks.

- Automate and Streamline Processes: Embrace automation technologies such as robotic process automation (RPA) and artificial intelligence (AI) to streamline supply chain operations. Automate repetitive tasks, optimize inventory management, and enhance order fulfillment processes. By reducing manual interventions, you can minimize errors, increase efficiency, and free up valuable resources.

- Foster Collaboration: Break down silos and foster collaboration among supply chain partners. Implement cloud-based platforms and digital collaboration tools to enable seamless communication, information sharing, and coordination. By promoting a collaborative ecosystem, you can improve responsiveness, agility, and innovation across the supply chain network.

- Continuously Adapt and Evolve: The digital landscape is ever-changing, and your digital supply chain must be adaptable. Embrace an agile mindset and stay abreast of emerging technologies, industry trends, and customer expectations. Regularly assess and optimize your digital supply chain strategy to ensure it aligns with evolving business needs and market dynamics.

By following these five steps, you can lay a solid foundation for a resilient and future-ready digital supply chain.

Conclusion

In a rapidly evolving business landscape, the digital transformation of supply chains has become an essential step for companies to thrive and stay competitive. As highlighted in the 2023 Supply Chain Technology Trends Report, the opportunities presented by digitalization are immense. Embracing technologies such as AI, automation, and data analytics can revolutionize your operations, enabling real-time visibility, streamlined processes, and informed decision-making.

By digitizing your supply chain, your company can work more efficiently, respond swiftly to market changes, and drive sustainable growth. Start by assessing your current capabilities, formulating a digital strategy, and collaborating with technology partners who can support your journey.

Now is the time to act. Digitize your supply chain, empower your company with renewed efficiency, and unlock the potential for increased profits and sustainable growth. Embrace the future of supply chain management through digitalization, and position your company as a leader in the dynamic and evolving business landscape of tomorrow.