Supply Chain Analytics: A Full Guide To Getting Started

In most enterprises, supply chains have evolved over the decades and become more intricate than ever. Each one can potentially produce large amounts of data from various sources available and all types of formats.

Companies have to network with various suppliers, partners, and other third parties to properly run supply chain management (SCM). And since there is a lot of data generated across the entire SC, leaders also need to extract intelligence out of it. Today it is possible thanks to affordable computing power available on a massive scale. In other words, combining Big Data and advanced analytics allows for building different instruments to get essential insights and transform information into business intelligence (BI).

What Is Supply Chain Analytics?

Today’s global supply chains consist not only of physical streams of product transportation but also of colossal information flows. SCA helps to use all verified and relevant data gathered by analysts, revealing meaningful patterns and insights.

The SCA Market

The global supply chain analytics (SCA) market size is projected to reach US$8.8 billion by 2025, which is almost a threefold increase compared to US$3.5 billion in 2020. Increasing volumes of data, the necessity to enhance supply chain productivity, and the rise of artificial intelligence (AI) in SCM fuel the market expansion.

However, multiple issues and errors related to using data hinder the market growth. This is where SCA tools come into play to enhance the situation, increase awareness of ongoing supply chain operations, and help leaders make accurate and efficient decisions to drive the bottom line.

Approaches to SCA

For the major sorts of data analytics – used in SCA as well — there are several possible approaches:

- Descriptive analytics looks at the historical data, processes it to get meaningful insights into how to act in the future with similar events. It ensures visibility and a unified source of trusted information collected from the entire supply chain.

- Diagnostic analytics looks at past events and finds out the causes of poor performance, so a corrective approach to be considered the next time. Diagnostic analytics identifies only the reason, not the solution.

- Predictive analytics aims to find out the potential outcome of future actions and their impact on the business. It is used to identify the most probable risks and inefficiencies.

- Prescriptive analytics predicts future results and offers actions based on the predictions and shows the supply chain executives the outcome of each solution.

- Cognitive analytics – IBM outlines this type of SCA, which helps address difficult issues using natural language. Simply put, cognitive analytics (CA) utilizes human-like intelligence (AI, deep learning, machine learning) to solve complex supply chain problems.

Looking at how rapidly the data sets are accumulating (2.5 quintillion bytes of data per day), we understand that data analysts have to use advanced approaches to processing it. Therefore, global enterprise leaders become more forward-thinking and bring their SCA to the next level by applying cognitive analytics.

CA exploits advanced AI and ML techniques, creating a competitive advantage for the business, giving real-time answers with the ability to navigate through large volumes of information and understanding the context, and calculating the most accurate decisions.

Challenges For Supply Chain Analysts In 2020

Due to the complexity of today’s supply chain environment, several critical challenges arise for a business to tackle, including:

- A gap between business goals and execution

- A need for instant visibility across the entire supply chain

- Poor production planning, resulting in high-priced asset underutilization

- A need for accurate demand forecasting to prevent insufficient/excess inventory and ensure safety stock levels

- A need for flexibility in the production, distribution, and transportation

- Failure to properly assess and prepare for supply chain risks

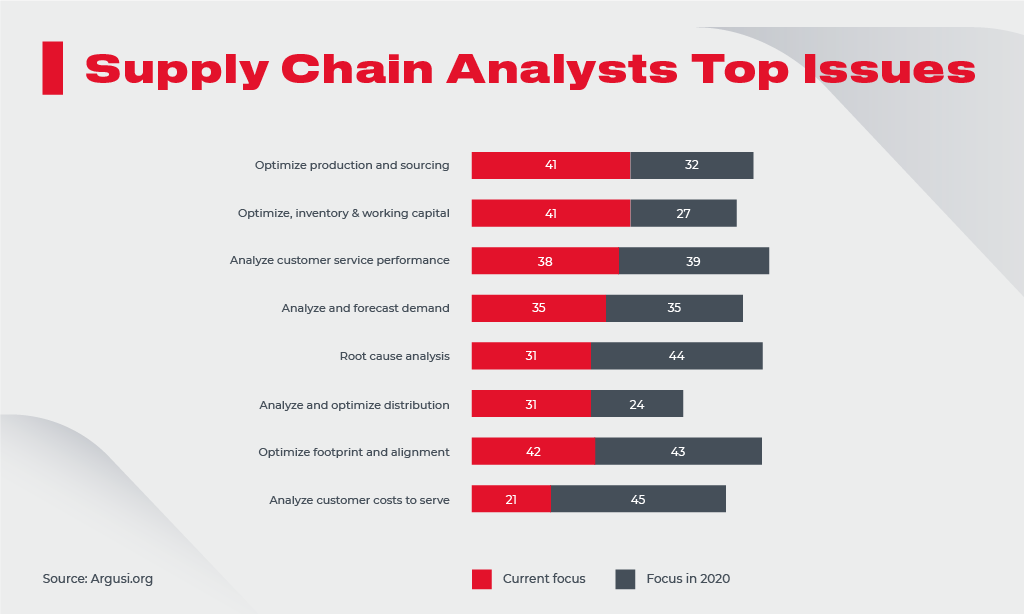

According to another study, supply chain analysts have to pay attention to the following issues in 2020:

Since the traditional SCA approaches mainly focus on past events data, it takes too long to get valuable insights and take practical steps to tackle a specific issue. The research showcases that under 25% of enterprises can instantly react to insights from SCA. That’s why it is crucial for modern supply chain managers and analysts to embrace the latest techs and advancements.

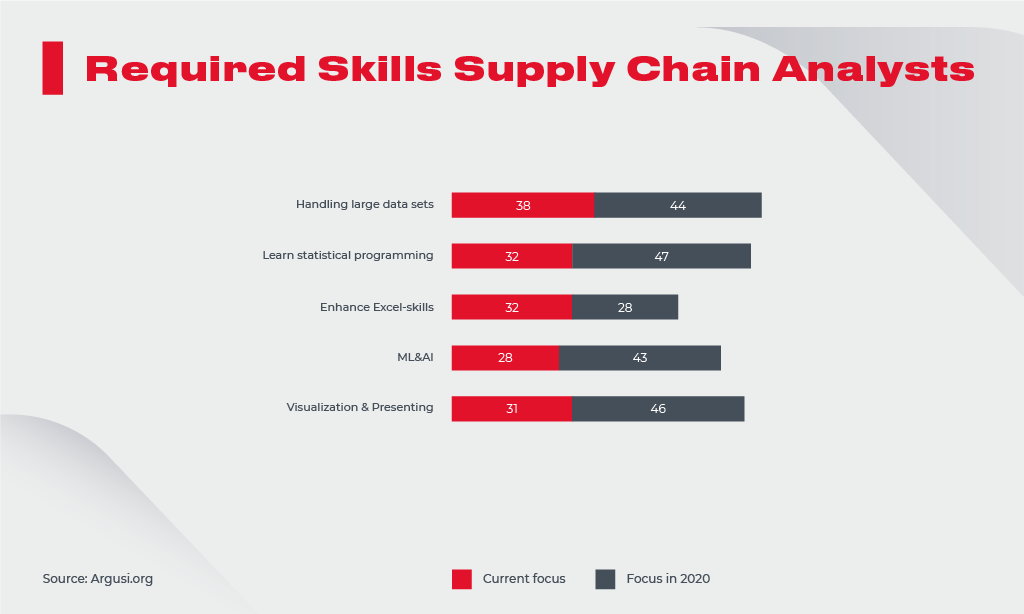

To combat the supply chain process’s key issues, accountable managers must master the following skills: management of large data sets, statistical programming, basic Excel, AI and ML, visualization, and presenting of data. The supply chain analyst will also require creative thinking to make the most out of the available data.

Why Is Supply Chain Analytics Important?

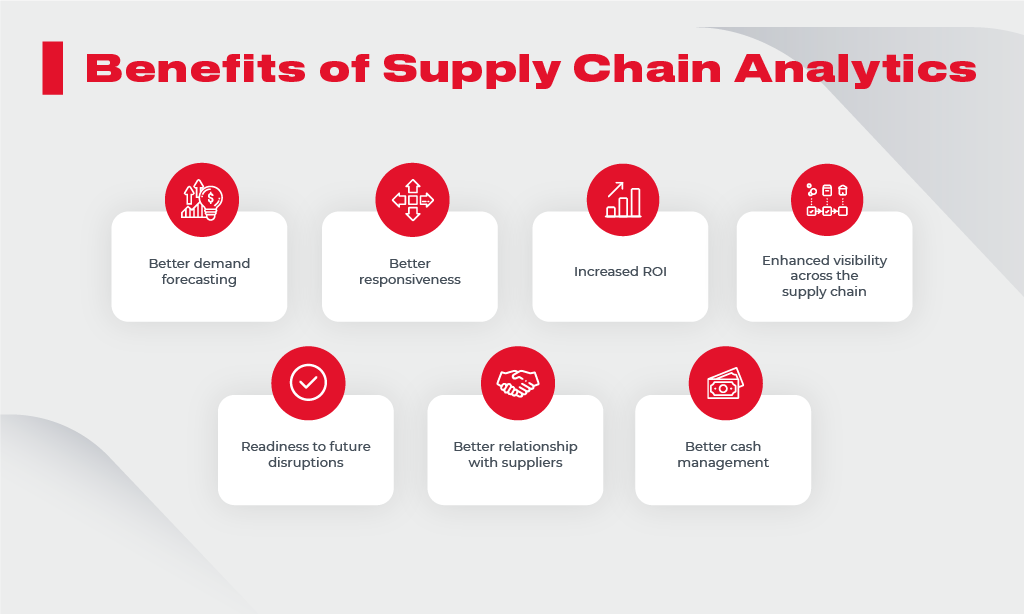

Applying smart analytics can benefit every link of a supply chain and tackle the main challenges. Enterprises can reap the following benefits:

Better forecasting of customer demand – It’s one of the most crucial components in the logistics chain. Companies can suffer dramatic losses in time, budget, and resources if demand planning is inadequate, inaccurate, and totally inefficient. By adequately analyzing customer data and past shopping trends, SCA can enhance demand forecasting. This enables a business to precisely determine the required inventory quantity to be in stock, minimizing overloading or insufficiencies, damages, and other demand-related issues.

Better responsiveness – Since SCA helps to calculate the required stock better, supply chain managers can predict the number of products to buy, products to remove, and products to add. All this enhanced the responsiveness of the enterprise to trends, disruptions, and various unforeseen events.

Increased ROI – A recent study shows that a third of surveyed companies revealed they had increased return on investment levels by applying analytics in the supply chain, in contrast with only 4% of businesses that didn’t succeed in improving ROI.

Enhanced visibility across the supply chain – Leaders can monitor the ordering process in real time and ensure that everything runs smoothly. Thanks to using big data analytics (BDA) and advanced techs such as IoT, blockchain, AI, supply chain managers know the exact location of the order and can adapt to changes if they occur during transportation. If appropriately used, SCA brings an enormous value by adding full control and visibility into the supply chain management.

Readiness to future disruptions – Organizations are now employing advanced analytics to run SCM most effectively. Advanced analytics lets you process structural and nonstructural data, providing organizations with timely notifications and alerts to respond to issues and make more accurate and profitable decisions. Also, BDA can generate inferences from disparate data sources and suggest insights to reduce risks without wasting money and affecting sustainability.

Better relationship with suppliers – Thanks to improved visibility while using SCA, executives can be better aware of their trading partners’ activities and effectiveness. Supply chain analytics enables company leaders to quickly notice which partners, suppliers, and intermediaries deliver the most profitable business. Also, they can decide which partnerships are reliable and worth cooperating with. With this information in place, C-level managers have a better position for handling price negotiations.

Better cash management – By improving demand forecasting and gaining more control over inventory levels, SCA enhances cash management as well. The ability to deliver orders on time and in larger volumes minimizes errors and damages, leads to higher customer satisfaction levels, and improves their loyalty. Therefore, companies can shorten the order-to-cash and cash-to-cash lifecycles and increase revenue by eliminating waste. The cash conversion cycle is the period between investing in product creation and receiving money from sold products. The shorter the cycle, the more cash firms get at their disposal.

The Supply Chain Analytics Tools And Techniques

In a modern, fast-paced, and full of disruptions environment, highly competitive companies can respond to changes almost instantly and recover faster thanks to leveraging supply chain analytics capabilities to the fullest. To succeed, they use specific tools and techniques. Let’s have a more detailed look at them.

There are various technologies leveraged to analyze data. Machine learning and artificial intelligence became widely used thanks to an algorithmic nature. AI is employed to build predictive models that can aid an enterprise to get ready for economic changes. Another popular technology, IoT (Internet of Things), is used to collect data from any component of the digital supply chain. Around 20% of carriers and 30% of third-party logistics firms use IoT, as the American Shipper study states.

The following are examples of using various supply chain analytics techniques to minimize and recover after emergencies as well as to foretell them more accurately:

Getting Real-Time Insights Through BDA — Companies can exploit publicly available data to monitor unforeseen events. For example, the pandemic Resource Center by Johns Hopkins delivers the latest updates on novel virus cases and mortality levels. Supply chain firms can use this information to measure the potential impact on workers, partners, suppliers, and areas.

Discovering Vulnerabilities Using Visualization — Visualization tools help companies measure the impact of unexpected events on the supply chain. This is crucial for enterprises with intricate supply chain networks spread all over the globe. Overlaying the emergency’s span onto different areas, first and second-tier suppliers and end-consumers can unveil the supply chain’s weak spots and increased risk exposure points.

AI and ML To Rapidly Respond To Changes — The combination of ML and AI enables enterprises to be ready for unpredicted events that may significantly affect the business process if not having proper SCA. For example, manufacturers can use ML-based algorithms to quickly discover changes in customer demand behavior and automatically adapt supply to ensure service continuity to major consumers.

The Gartner survey finds out that among the most successful companies (those utilizing two or more approaches to SCA), 96% use predictive analytics, 85% use prescriptive analytics and 64% use artificial intelligence.

Measuring Emergencies Using Simulation-Based Predictive Analytics — While taking urgent steps to alleviate the short-term consequences of the disruptions, companies now are centering their attention on dealing with mid- and long-term emergencies that are likely to occur. First of all, the supply chain managers are trying to measure those events’ impact on their business. For example, a high-tech corporation can use simulation-based predictive analytics to analyze the possibility of strikes in the port and imitate their impact on their capacity to satisfy customer demand.

Adapting SCM to Business Changes Using Long-Term Forecasting — Employing long-range forecasting, companies can measure the results of disruptions taking into account various situations. They can use optimization modeling to make the supply chain more resilient. In 2019, the China-US trade conflicts provoked many companies to consider moving their manufacturing assets from China to Vietnam. When modeling their network, the priority was to increase the supply chain’s resilience and agility, notwithstanding additional costs required to achieve them.

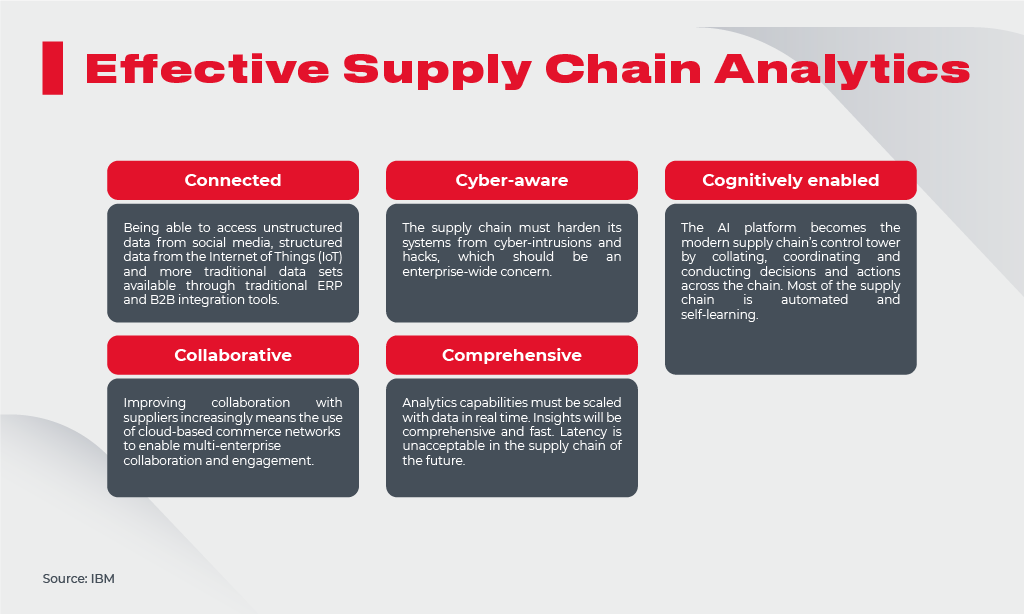

Now is the time to invest in analytics. In this age of highly complex supply chains, most companies agree that analytics is a must-have. The ongoing pandemic drives the necessity for reliable supply chain data analytics. Without adequate SCA, enterprises will fail to measure the impact of immense and unexpected changes on their mid- and long-range network policies. To understand how an effective supply chain analytics can be identified, consider the five characteristics suggested in the IDC report:

Supply Chain Analytics Use Cases

This section demonstrates some practical applications where SCA can help increase supply chain performance.

Forecasting Customer Demand

Forecasting customer demand is a top priority for companies and manufacturers, especially during peak periods for shopping such as holidays, seasonal sales, etc. By determining the most notable shopping preferences in their consumers, organizations get better control over the stock and speed up supply chain processes to ensure timely deliveries. In addition to analyzing shopping behavior, managers can utilize data from marketing tools, combine this data with current market trends, and generate more context for accurate decision-making.

Invoice Details Reporting

Procurers and financial managers are much concerned about detailed invoices within the supply chain operations. They want to know the enterprise’s expenses depending on goods, services, location, and suppliers. Analyzing this information, managers get insights on how fast the transactions are processed, how often they were blocked or rejected, which in summary identifies factors affecting the cash-to-cash cycle. Supply chain managers, in turn, find out the best-performing partners.

Inventory Tracking

Keeping track of inventory helps organizations consolidate inventory data with other components of SC to assess supply chain performance. Consider, for example, a world-renowned transport manufacturer Toyota with an okay functioning ERP system across all regions with its plants. The enterprise requires enhanced visibility of incoming advance shipping notices (ASN) to increase its just-in-time manufacturing efficiency. With thousands of suppliers regularly delivering to each plant, the corporation needs full visibility across all regions with working factories.

Tracking Partner Efficiency

Since all companies have a significant interest in their partners’ performance, SCA can help identify those who perform top and those who, on the contrary, deliver poor services, waste time, and budget. Applying SCA tools here means eliminating undesirable relationships while preserving reliable partners and achieving the best results of proactive cooperation.

P2P Reporting

Procure-to-pay (P2P) is the process of requesting, buying, receiving, paying for, and accounting for products and services. That’s why accurate supply reporting gives evidence of the amount of business the enterprise is doing with each of its suppliers and how well each supplier is operating. SCA plays a vital role, as knowing the actual expenditures with the suppliers, supply chain costs are easier to control and save.

How To Build Your SCA Strategy

Being armed with all this knowledge, enterprise leaders can build a robust SCA system within their supply chain strategy. Supply chain analytics can help the company become analytics-driven and more successful. To get started, have a sneak peek at these recommendations:

1. Define a business problem and establish KPIs

Company executives first need to define the fundamental difficulties and gaps as well as KPI values that will be utilized to analyze and resolve the problem. A company probably needs to increase revenue streams, optimize inventory, or improve order fulfillment and timeliness of the deliveries. This is the first thing to do – find out and understand the problem. With the root cause analysis (RCA), leaders and managers can reveal vulnerabilities and address them to increase overall performance.

2. Discover the needed data

When objectives and KPIs are prepared, it’s the turn for data to be analyzed. Company leaders should check the business departments and find out units where data has already been collected and analyzed. But the departments may have poor communication with each other, which leads to inefficiencies of their analytics. To build a fully transparent and traceable supply chain, enterprise leaders should unite the analytics gathered from different siloes. After discovering what data is available at your disposal, match it with your business goals, and reveal the voids to be filled.

3. Have a talented team in place

A robust SCA strategy requires a diverse team of specialists to be in place – from professional executives who set the tone of the whole initiative, to Big Data analysts, and to skilled software developers to implement the most advanced tech solutions. Outsourcing a part of the team or the whole one may be the right decision to entrust the entire process with experienced people. Look no further than speaking with Innovecs today. We’d love to talk and provide you with a detailed analysis and consultation.

4. Pick the right tools

After hiring best in class talent, company executives may rest assured their data analytics are in safe hands. Selecting the proper solutions for a business is critical, as you have to define whether you need an autonomous solution for SCA or integrate the tool into the business environment. An outsourced team can help choose suitable instruments and technologies to satisfy both budget and time requirements.

5. Evaluate your achievements

The success of the supply chain analytics strategy is usually seen in increased financial and overall business performance, increased revenues, better demand planning, reduced risks, and security issues. The company and supply chain leaders have to keep track of the benefits they have reaped, as it is also a part of SCA. Regular monitoring of results helps to run the business smoothly and without dramatic failures.

One thing to remember is that measuring too much or too little may be harmful to your operations. Also, accountable managers shouldn’t utilize erroneous and outdated data, leading to wrong decisions and even more severe problems.

Conclusion: Building a Robust SCA With Innovecs

Giving answers to what supply chain analytics is, additionally, why it’s crucial for modern businesses, we found out that the core element of success is building a technology-driven analytics system and keeping track of every link in the network. Today’s SCA is helpful in many areas, including:

- Improving customer demand forecasting

- Increasing business responsiveness

- Increasing ROI and expediting cash-to-cash cycle

- Enhancing the accuracy of emergency prediction and its mitigation

- Strengthening relationships with top-performing partners

To achieve these benefits, companies choose various techniques and tools. For example, supply chain managers can employ AI and ML-based solutions to automatically analyze colossal data volumes within minutes. The SCA application areas are also vast – you can use it for invoice reporting, inventory optimization, partnerships reporting, and tracking the procure-to-pay process.

Once you’ve decided you need a robust SCA platform, you can partner with Innovecs as it is a perfect option. We have broad-spectrum expertise in custom supply chain software development, backed by the latest technologies such as AI, ML, BDA, IoT, and more. Feel free to contact us and get more information.