Why IoT Architecture is Beneficial for Supply Chain Management

Originally published at https://www.business2community.com/business-innovation/why-iot-architecture-is-beneficial-for-supply-chain-management-02315025

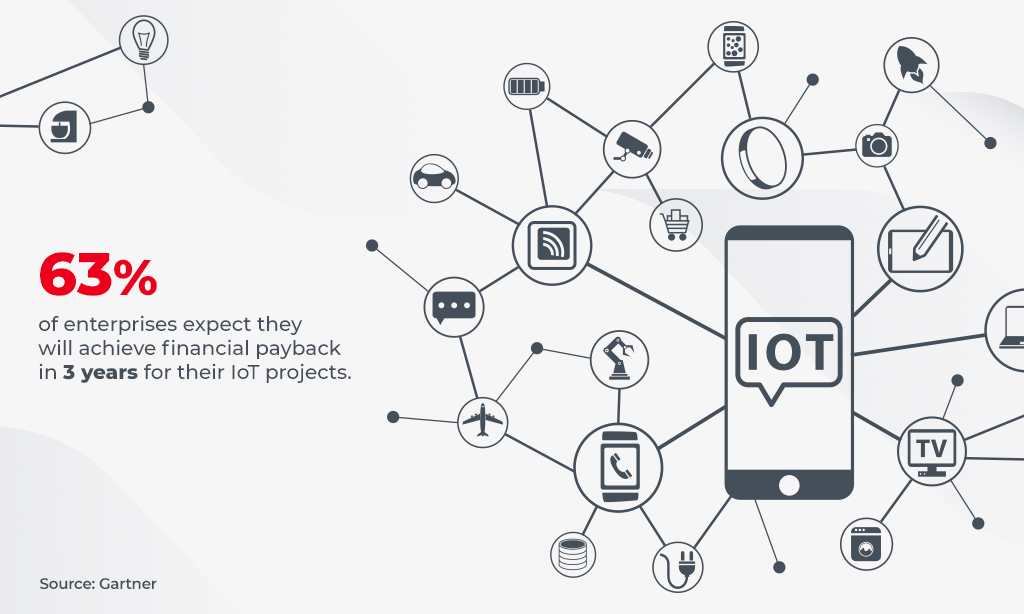

Gartner forecasted that more than half of major new business processes will consolidate some elements of IoT by 2020. Moreover, up to 26 billion smart devices connected to the internet will be installed, making some $300 billion by the end of the decade.

Also, the study shows that a thirty-fold increase in internet-connected physical devices will dramatically alter the way the supply chain works. Besides, the enterprise and automotive Internet of Things market will grow to 5.8 billion by the end of 2020, meaning a 21% increase from 2019.

How IoT Architecture Changes Supply Chain

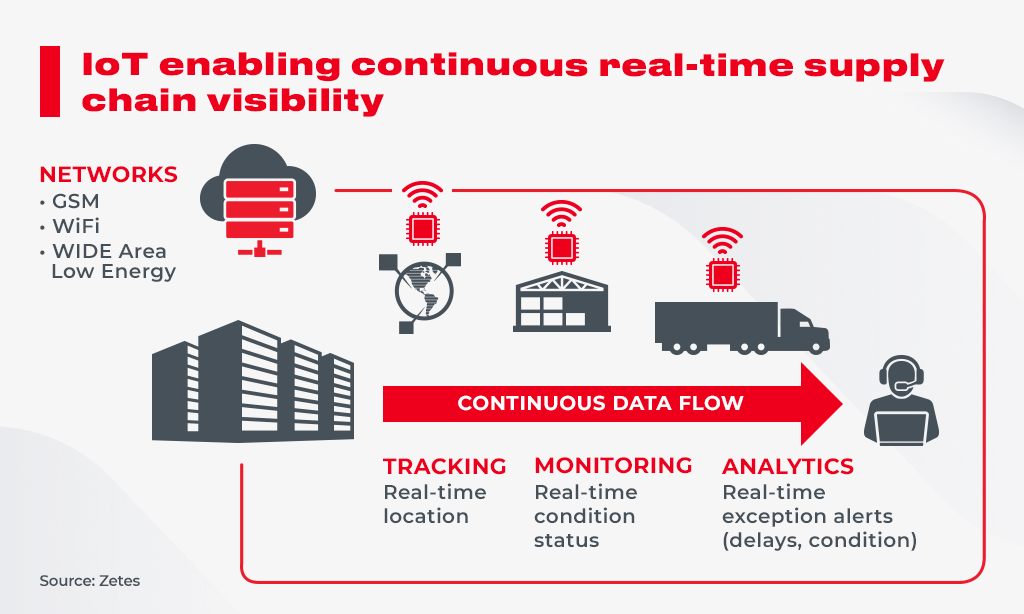

Tracking and monitoring are the primary purposes of IoT deployment in SCM (supply chain management). The technology allows warehouse and fleet workers to monitor their cargo movement and inventory. However, there’s more to the IoT than its asset management potential. Here are the key insights of how IoT can reshape the supply chain:

- Real-time location-tracking. The Internet of Things offers supply chain managers a regular stream of real-time information on the location of the goods. In case the product is shipped wrongly, you immediately get alerted and can track the delivery till the destination.

- Storage environment monitoring. Thanks to the special sensors, supply chain managers can check the transportation conditions of the goods — from the temperature inside the vehicle, pressure, humidity, and other factors that could compromise the product’s quality.

- Predict the transportation and the arrival of the product. The amount of options supply chain managers get using IoT devices improves the quality of decision-making and increases the accuracy of delivery forecasts. Real-time tracking enables a supply chain IoT company to predict the final delivery date, identify and mitigate risks before they occur.

Improve emergency planning. IoT smart devices dramatically help supply chain managers to plan routes, taking into account the unforeseen events that could happen on the highway. The Internet of Things handles all data needed to create a flexible contingency plan and prevent existing delays.

5 Benefits of Implementing IoT Architecture in SCM

With the Internet of Things gaining popularity, more companies seek to reap the benefits of technology in the supply chain. If you are wondering how IoT architecture can boost your company’s efficiency and diminish some operating costs, check this list of IoT benefits for SCM.

- Higher speed. The connection of route-planning tools to the IoT SCM platform increases the entire supply chain speed exponentially. The Internet of Things reduces the feedback circle, allowing for faster decision-making, delay risks mitigation, and improved efficiency of locating goods within the warehouse.

- Improved flexibility. IoT systems work faster and are easily accessible rather than on-premise ones. A supply chain manager ensures that all parties involved in the process have access to specific data by implementing a cloud-based IoT platform. Also, a connected IoT solution presents all collected insights in a way that’s appropriate to a particular scenario, helping guide workers through the supply chain.

- Higher accuracy. Solutions based on the IoT architecture give managers in-depth information on the lifecycle of the goods, helping retailers and supply chain managers know the exact product unit quantity to be ordered. The IoT solution reduces human errors by helping identify parcels and navigating drivers on the way.

- Improved segmentation. The technology allows retailers and supply chain managers to segment products according to the target audience. Thanks to IoT technology, all company stakeholders can have a better idea of what customers are attracted to a specific product.

- Increased efficiency. IoT expands the capabilities of connected employee-oriented platforms. Such tools like smart glasses help consult warehouse workers seamlessly to ensure they save time while completing a task. Besides, IoT collects efficiency-related data and brings more awareness into resource and labor management. Thus, the technology allows supply chain managers to be assured that all the parties involved in the working process perform the best way.

Challenges of Using IoT Architecture in Supply Chain Management

Even though digital transformation is spreading widely, most companies still use outdated legacy systems for managing deliveries and tracking assets. Implementing solutions based on IoT architecture into an environment that is the patchwork of the old and the new is a challenge for most managers, and here’s why:

Lack of Skilled Team

Adjusting to managing internet-connected platforms usually requires intensive training of warehouse workers and transport drivers. Explaining the security rules and describing the guidelines for using corporate platforms is a time-consuming process.

Finding a team qualified enough to create a solution tailored to the company is not easy, considering the lack of IoT training. With the global tech talent shortage in mind, supply chain executives should understand that hiring an experienced team won’t be easy.

Increased Data Storage Issues

Large data pools are one of the many benefits the IoT offers supply chain managers. However, with that advantage comes the need to acquire enough servers to store and process all the captured data. Company leaders will need to create data governance policies, find data scientists and analysts to ensure they generate the right reports from IoT-based insights.

Security Threats

Developing a secure IoT architecture is another task supply chain supervisors have to perform before moving all processes to connected platforms. Vulnerabilities in data processing and storage can lead to external attacks and leaks, undermining the company’s reputation and increasing the cost of failure.

The good news is that, by leveraging machine learning (ML) and cryptographic hardware monitoring, company leaders can safely mitigate outside security risks and access all stored data.

Connectivity Problems

IoT heavily relies on having a reliable internet connection. Since fleet drivers are going from one location to another, there’s not always a stable network. As internet coverage expands and 5G becomes widely available — the connectivity issue is likely to be soon the problem of the past. So far, supply chain managers have to put up with this obstacle.

Bandwidth is another issue to keep in mind when adopting an IoT solution for SCM. Connected systems typically consume much bandwidth and need a high-level server farm to run smoothly.

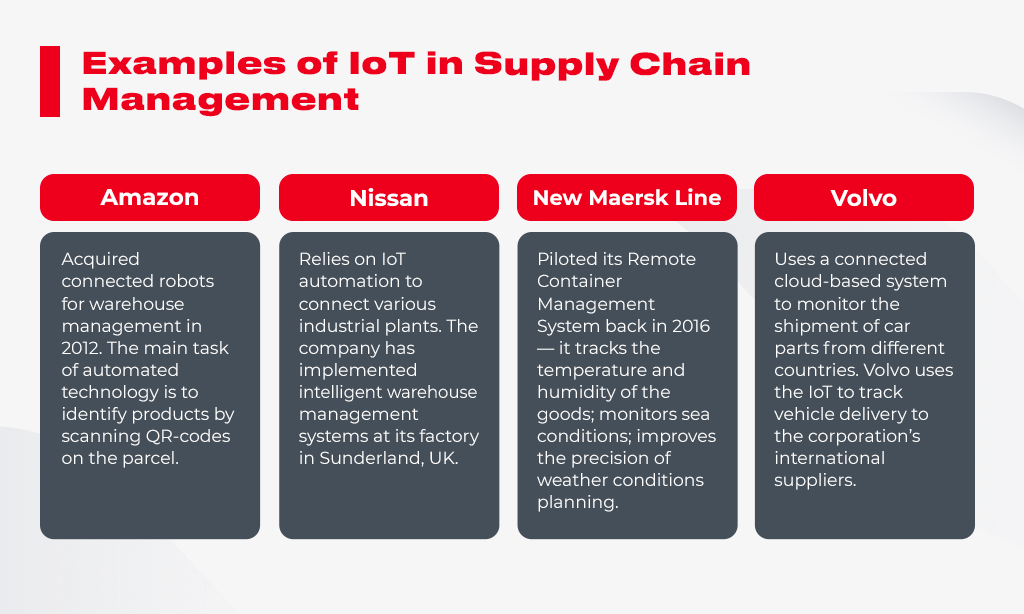

Use Cases for the IoT

Here are some examples of levering IoT solutions in retail and manufacturing supply chains.

- Farmers can use IoT tools to check soil moisture and decide the best time to plant or harvest.

- Businesses can use IoT-enabled cameras to detect defects and reject damaged products.

- Chemical companies can ensure that raw materials are safe by monitoring and triggering an alarm if they’re affected by high temperatures.

- Manufacturers can benefit from immediate production by preparing goods just as they’re scheduled to arrive.

- Food retailers can control the temperature and humidity of products in storage to ensure they reach stores in excellent condition.

- Retailers can work with specialized logistics parks to track products as they arrive at distribution centers.

Tips to Successfully Implement Architecture of IoT

Gartner suggests some lessons from early IoT adopters: those companies who work through the challenges of implementation to deliver compelling business value.

Involve the CIO Early

The Internet of Things had a not so good start in some organizations than initially anticipated. Nevertheless, the IoT continues to mature, adopters are getting better at reaping the benefits. All in all, the IoT projects are more likely to succeed if the Chief information officer (CIO) is involved from the very beginning.

A Gartner survey found that 80% of companies that have embraced IoT showed they are achieving better-than-expected results.

Nick Jones, a distinguished VP and analyst at Gartner, says that while the report indicates only self-reported success, real perks from IoT are displacing the hype.

“What we found is that CIO involvement in IoT is critical – projects are more likely to succeed if they are involved,” says Jones.

Know Possible IoT Pitfalls

Security and privacy range first in the list of technical challenges faced by IoT adopters. According to Gartner, it will last until 2025 due to a skill gap, ever-changing threats, a blurry vendor landscape, and immature standards.

“IoT is not just a technical problem to be solved,” says Jones. “To move IoT beyond the pilot phase, think proof of value, not proof of concept. Technical POCs do not convince executive leadership to spend money on IoT.”

The non-technical issues involve:

- Political and organizational issues

- Budget challenges

- User experience with IoT sensors and devices

Workforce issues around learning new practices is also a big issue. For example, a switch to automated monitoring could trigger trade unions to get involved.

Enterprises face even more challenges, such as fluctuations in the quality and availability of local infrastructure and communications services, global technical support across time zones, local regulations, and cultural barriers, such as attitudes to robotics or artificial intelligence.

IoT Supply Chain Development with Innovecs

Recognizing the growing demand for automation and the opportunities digital transformation brings along is a significant step towards advancing operating efficiency. However, it’s just as necessary to find a skilled team for IoT solutions implementation.

If you want to boost your supply chain management (SCM) and bring more visibility to every step of the way, Innovecs is the right team in charge of IoT implementation for your business.

We use technologies that help businesses accomplish these objectives:

- Collect and process data;

- Find patterns and build precise predictions with machine learning;

- Access all received data in real-time.

With the developed tools supporting all the common environmental sensors, you can monitor the temperature, humidity, concentration of chemicals and gases in the air, pressure, and other variables.

Conclusion

The Internet of Things has a wide range of IoT applications in supply chain management. It enables the tracking and monitoring of goods, brings more visibility to the communication, and increases planning accuracy.

An IoT-based platform is an excellent investment for both small businesses and large corporations, as long as you have a clear vision of what you want the technology to accomplish for you. Onboarding a team of experts for the design and development stage is crucial as well. To ensure your IoT solution for the supply chain follows the modern tech trends and is fully functional, reach out to Innovecs — an excellent team of software developers.